- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Principles and characteristics of laser welding machine mold repair!

The working principle of the laser welding machine is to use laser deposition welding, which uses laser high heat energy and concentrated fixed-point welding technology to effectively handle all small parts of welding and repair work, making up for the shortcomings of traditional argon welding and cold welding technology in repairing fine surfaces.

The laser welding machine can weld various metal steels, such as S136, 718, SKD61, SKD11, 2344, NAK80, 8407, P20, stainless steel, beryllium copper, aluminum alloy, titanium alloy, etc. After welding, there are no sand holes, pores, collapse, deformation, high bonding strength, firm, and not easy to fall off.

In addition to the adjustable laser energy, spot diameter, pulse width and working frequency, the laser welding machine repairs the mold and also adjusts the single pulse waveform specifically for welding different materials (the pulse waveform is slightly different when welding different materials such as steel, beryllium copper, aluminum, etc., and the pulse waveform also affects the hardness after welding).

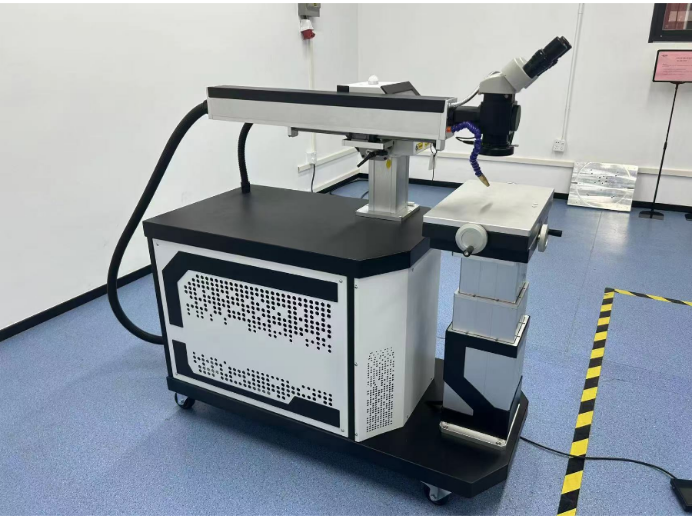

The laser head can be easily separated from the main unit. In addition to welding and repairing precision molds such as mobile phones and digital cameras, it can also repair large molds such as automobiles and motorcycles.

The laser welding machine has the following advantages for repairing molds:

● The diameter of the laser welding point is only 0.2mm~2.0mm

● The heating range is small, and there will be no defects such as deformation, pores, sand holes, collapse, etc.

● The impulse of the laser makes the welding effect firm, the adhesion is strong, and it is not easy to fall off

● Processable materials such as mold steel, stainless steel, beryllium copper and precious metals

● Can repair cracks, broken corners, mold edges, and worn sealing edges

● Can be ground into a smooth surface after welding

● Can be welded on extremely hard materials (~HRC 60)

Related product links

Welder News

Welder News