- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What is laser cleaning and pulsed laser cleaning?

The laser in the laser cleaning machine has a specific wavelength. The high-energy beam of a specific wavelength is absorbed by media such as rust layers, paint layers, and contamination layers. Then a rapidly expanding plasma is formed. At the same time, shock waves, shock waves, etc. are generated, which turn the contaminants into fragments and remove them. The base layer of the material does not absorb energy. Therefore, laser cleaning will not damage the surface material of the object being cleaned. The original material will not reduce its surface finish.

Compared with traditional cleaning methods and continuous laser cleaning methods. Traditional cleaning methods include chemical cleaning and mechanical cleaning. Pulse laser cleaning machine has the following advantages and disadvantages:

SAN LASER pulse laser cleaning is an environmentally friendly cleaning process. It is relatively "green" and belongs to "dry cleaning". SAN LASER's pulse laser cleaning machine does not require the use of any consumables. We do not use detergents or chemical solutions. But the cleaning effect of the pulse laser cleaning machine is much higher than various traditional cleaning methods.

The cleaning application range of SAN LASER pulse laser cleaning machine is very wide. SAN LASER pulse laser cleaning machine has eight cleaning modes. The operation interface of SAN LASER pulse laser cleaning machine provides 7 cleaning modes. The operator can switch the cleaning mode by clicking the scanning mode option on the operation interface.

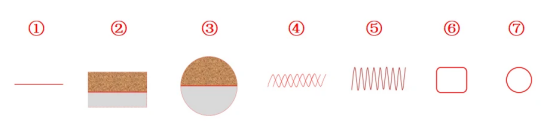

7 cleaning modes:

1. Linear mode,

2. Rectangular mode,

3. Circular mode,

4. Sine mode,

5. Double helix mode,

6. Free mode,

7. Circle.

Therefore, the pulse laser cleaning machine produced by SAN LASER CNC has the following advantages:

It can clean and fit different curved surfaces and different heterogeneous surfaces. It can clean very fine particles as well as large areas of pollutants and impurities. SAN LASER pulse laser cleaning machine can accurately remove various rust and paint. As well as various surface impurities such as coatings.

SAN LASER's pulse laser cleaning machine is suitable for almost all solid materials. In many cases, only dirt can be removed without damaging the substrate. Relatively continuous laser cleaning machines can clean rust and paint layers. But continuous laser cleaning will leave cleaning marks on the substrate.

Different modes can be selected according to the requirements of the cleaning material. The shapes of different lasers can be switched freely. To achieve the customer's cleaning needs for specific areas and specific locations.

The operation of the SAN LASER pulse laser cleaning machine is not only very simple. It can also reduce labor costs.

It can control the machine to perform the cleaning process in a non-human contact manner. The laser cleaning parameters can be set on the operation interface of the pulse laser cleaning machine. Includes:

1. Laser power,

2. Laser frequency,

3. Pulse width or scanning mode,

4. Scanning speed,

5. Number of scans and scanning range (width, height), etc.

Related product links

Welder News

Welder News