- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What is MOPA Laser? Pros and Cons of MOPA Laser Technology?

When you hear about MOPA laser engraving technology, you hear about special features such as color engraving, deep engraving. So how many colors can be engraved? How deep can it be engraved? And what are the pros and cons of MOPA laser engraving technology? What is the difference of MOPA laser compared to other lasers?

In this article, we will explain the basic information to give you a better understanding of MOPA laser engraving technology.

· What is MOPA Laser?

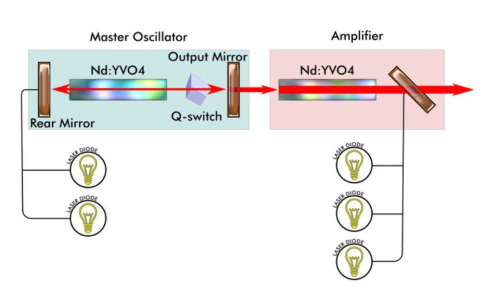

The MOPA (Master Oscillator Power Amplifier) Fiber Laser Marking Machine is an advanced type of laser marking machine that uses Fiber laser technology along with a two-stage process to enhance the laser signal.

This technology allows for precise control of the width and pulse frequency, which is important for a variety of applications, including engraving, marking, cutting, and welding.

MOPA Fiber Laser machines offer superior performance in engraving quality and flexibility compared to traditional laser marking machines. They can be used to engrave on a wide spectrum of materials, including those that jump inductively, without causing thermal damage, thanks to their ability to adjust the pulse length. Furthermore, they can produce different colors on certain metals, like stainless steel, by adjusting the pulse length and frequency.

· Materials that can be etched with MOPA lasers

Due to the larger range area in the pulse length, the application range of MOPA machines is also larger. A MOPA laser machine can produce precise, high-contrast engravings on the following materials:

Metal: Including stainless steels such as aluminum, copper, brass, titanium, gold, silver and other alloys.

Coated metal: This is a metal that is coated with materials such as paint, oxidized aluminum, or other surface treatments. The machine can selectively remove the coating to create high-contrast traces.

Plastics: Here are some common plastics, these plastics can be etched using MOPA laser technology. Results may vary depending on the type of plastic, with some achieving a clear, easy-to-read trace

Sensitive Materials: MOPA laser machines are suitable for marking sensitive materials that may be damaged due to the high amount of heat from Fiber lasers. Sensitive materials can be thin plastics, films, some types of oxidized aluminum and silicon

· Advantages of MOPA Laser

Pulse width adjustment

The adjustable pulse width increases the ability to control a wider range of materials than conventional fiber lasers. Resulting in suitability for more applications.

High Accuracy and Quality

MOPA Laser technology is well-known for creating higher contrast etching marks on certain materials that make the engraving clearer and more recognizable.

Suitable for a wide range of materials

MOPA Laser machines can engrave on a wider range of materials than many other laser machines, including sensitive materials that can be damaged by high heat.

Color engraving

MOPA laser machines can produce a wide variety of colors on certain metals such as stainless steel and titanium, by adjusting the pulse length and frequency, a feature not found in many other lasers

Reduces heat damage

Because the pulse length characteristic can be shortened, MOPA lasers can reduce the area affected by heat on the material being processed. Helps reduce heat damage and discoloration on the engraved material, especially with sensitive materials.

Performance and longevity

Like Fiber lasers, MOPA lasers also have a long energy efficiency and operating life, which can be up to 100,000 hours.

· Disadvantages of MOPA Laser

Etching Speed

Engraving speed is an important factor that laser machine users care about. However, when you use a MOPA laser machine with the intention of engraving colors, the engraving speed is a problem that you have to consider. When it is necessary to engrave with color effect, the machine needs to mark at high frequencies with a very small hatch effect. This results in very detailed resolution resulting in a longer marking time than another fiber laser machine marking colorless on metal. For this reason, you should reconsider buying this type of technology if you plan to engrave hundreds, thousands of samples per day. This technology is designed to mark a small number per day

Rust phenomenon

When we laser engraving MOPA the material we use will be stainless steel, copper, titanium, nickel, silver etc. The color engraving on these materials will be shallow marks rather than deep ones. Although only a shallow trace, the color produced is a chemical reaction on the surface of the metal, which means that the laser has altered the surface of the metal, altering their anti-corrosion properties. As a result, there will sometimes be a small rust phenomenon a few months after engraving.

Investment costs

The design of MOPA laser sources requires more complexity than other types of fiber laser sources because of its very high and low frequency range characteristics and it requires more sensitive components. For these reasons, the cost of a MOPA laser source is somewhat more expensive than a normal fiber laser, although at first glance the shape of these two types of sources looks similar.

· Conclude

Through this article, you will have a basic view of MOPA lasers so that you can know the pros and cons of this technology. When starting to buy a laser machine, the most important thing is that you need to understand your needs. If your need is to engrave colors onto materials, then MOPA lasers are a great option.

Company News

Company News