- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

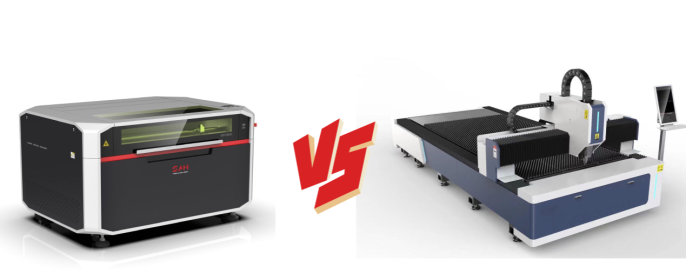

What is the difference between fiber laser cutting machine and CO2 laser cutting machine?

What is the difference between fiber laser cutting machine and CO2 laser cutting machine?

(1) Equipment maintenance costs are different: CO2 laser cutting machines have high maintenance costs, front and rear mirrors are expensive, and turbine bearings have a lifespan of only 8,000 hours, so replacement costs are expensive. However, fiber laser cutting machines are maintenance-free, have basically no consumables, are capable of operating in harsh working environments, and have a high tolerance for dust, vibration, impact, humidity, and temperature.

(2) Different processing costs: CO2 laser cutting machine processing not only produces gas consumption, but also has a photoelectric conversion rate of only 8% to 10%. Fiber laser cutting machine does not require any other consumption during processing, and the photoelectric conversion rate reaches 30%, which is relatively energy-saving.

(3) Different technologies: The laser structure of the CO2 laser cutting machine is complex, the maintenance cost is high, and the beam divergence is large during processing, so it is not suitable for large-format processing. The cutting seams are thin, but very slow when processing thick plates. The laser characteristics of fiber laser cutting machines are reflected in miniaturization, intensification, high brightness and high conversion rate. When processing thin plates, the cutting speed of fiber laser cutting machines with the same power is 2-3 times higher than that of carbon dioxide, and the cutting section is smooth.

Cutter News

Cutter News