- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What is the market prospect of handheld fiber laser cleaning machine?

In order to achieve the functions required by the design products and the market, daily industrial products and professional industrial products must adopt one or more metal surface treatment technologies and processing technologies.--handheld fiber laser cleaning machine

In the process of electroplating, phosphating, painting, welding, packaging and integrated route installation of industrial products, it is necessary to remove surface grease, dust, rust, residual solvents, adhesives and other wastes to ensure the quality of the next technical process. The current standard of laser cleaning machine of laser marking machine manufacturer. The cleaning methods widely used in the cleaning field include mechanical cleaning, chemical cleaning and ultrasonic cleaning, but under the constraints of environmental protection and the requirements of the high-precision market, its application is greatly restricted.

1. Mechanical methods cannot meet the high-cleanliness cleaning requirements;

2. Chemical cleaning methods are prone to air pollution, and the cleanliness obtained is also very limited; especially when the stain composition is complex, it is necessary to use a variety of cleaning agents to continuously clean in order to meet the surface cleanliness requirements;

3. Although the ultrasonic cleaning method has a very good cleaning effect, it is helpless against the cleaning of submicron dirt particles. The size of the cleaning tank limits the scope and complexity of the processed parts, and the drying of the workpiece after cleaning is also a major problem.

It must be recognized that my country's manufacturing industry is now large but not strong, which is particularly prominent in the surface treatment industry. Modern manufacturing should adopt powerful metal surface treatment technology to replace the backward production capacity and insufficient strength of the domestic metal surface treatment industry. This is a key challenge faced by my country's manufacturing industry in the process from large to strong. The challenges faced by the metal surface treatment industry have brought strong pressure to the industry, but also created huge opportunities.

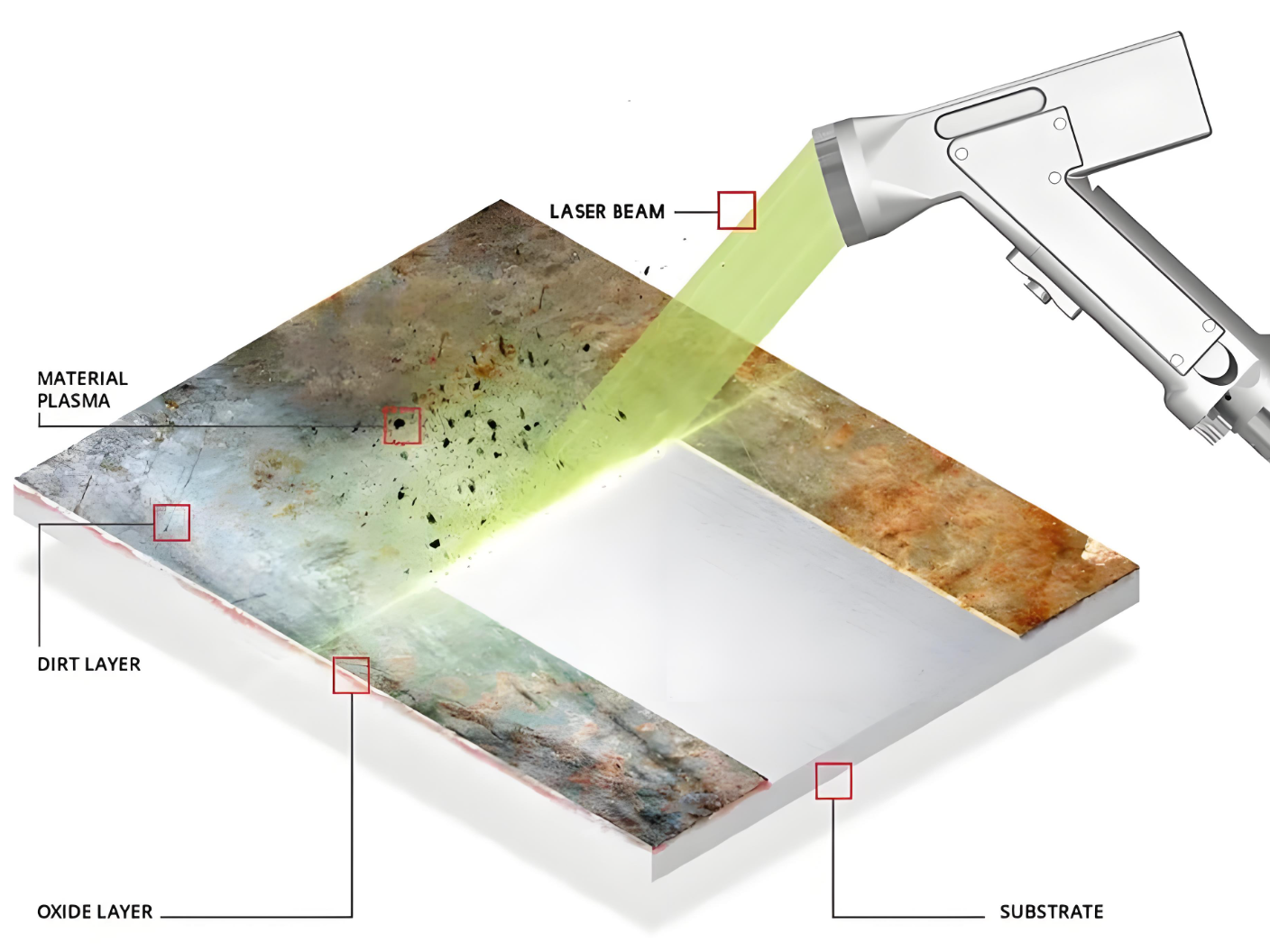

With the advent of the Industrial Production 4.0 era, some new intelligent industrial products have entered the market, and these new products all need to adopt metal surface treatment technology, and the production capacity of the settlement port must be transformed into an excellent production force. Laser cleaning technology is a new cleaning technology that has developed rapidly in the past decade. It has gradually replaced the traditional metal surface treatment cleaning process in many industries due to its many advantages. It can be used to clean various surface wastes, has little air pollution, and can ensure that the substrate is not damaged. This method is a supplement and extension of traditional cleaning methods, and has shown broad application prospects with its many advantages. Compared with traditional technologies, laser cleaning technology has the following characteristics.

(1) It is a "dry" cleaning process that does not require detergents or other chemical solutions, and its cleanliness is much higher than that of chemical cleaning processes;

(2) The scope of waste removal and the scope of applicable plates are very wide;

(3) By controlling the laser processing parameters, pollutants can be effectively removed without damaging the surface of the plate, making the surface as good as new;

(4) Laser cleaning can be easily automated and reduce manpower;

(5) Laser cleaning is efficient, time-saving and labor-saving;

(6) Laser decontamination equipment can be used for a long time and has low operating costs;

(7) Laser cleaning technology is a "green" cleaning process. The waste removed is solid powder, small in size, easy to store, and mostly non-polluting.

Related product links

Welder News

Welder News