- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

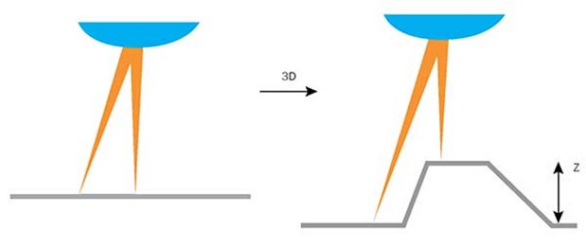

Why is 3D laser marking important?

3D laser marking is important industrially and commercially as 2D laser marking. Below is some importance of the process above the 2D marking.

It is very flexible

3D laser marking is more flexible as it is suitable for different surfaces and shapes. For example, you can use it to mark products having round, cylindrical, conical, concave/convex, or triangular shapes. This is possible due to the 3D laser machine’s ability to adjust the laser beam position and focal length.

Ideal for deep engraving

3D laser machines are also more suitable for deep engraving due to their height control. This is unlike 2D laser machines, where a sharp drop in energy can occur as the laser shifts position leading to less marking quality.

Multi-color Markings

3D laser marking machines are more suitable for multi-color marking. The difference in height and laser intensity leads to an improvement in multi-coloring. This is an important aesthetic parameter that occurs via the process.

Better personalization

3D laser markings have better aesthetic value than 2D markings. The markings stand out, making them unique and beautiful. Although making the 3D markings might be challenging, designers can let their minds run wide to create a perfect 3D gift.

Quality marking

3D laser marking is better than other 3D marking systems because it delivers high-quality marking. However, this depends on the type of machine you are working on. If you want to know more about the machine, you can contact us.

Suitable Materials for 3D Laser Marking?

Unlike 2D laser marking, not all materials are compatible with 3D laser marking. For example, the process is unsuitable for stone because of its hardness. Below are the best materials for the process

Hardwood

There is the most common 3D laser marking materials. It is well-suitable due to its aesthetics. While the material is burnt during the process, cleaning is easy using water.

Acrylic

This is the second most common material for the process. It is harder than wood. However, it has a good impressive melting point. As a result, it is capable of 3D laser marking.

Medium Density Fiberboard (MDF)

MDF is the perfect material if you are looking for a material you can mark and paint later. It is soft, affordable, and accessible.

Metals

Metals such as aluminum, stainless steel, copper, etc., are also compatible with 3D laser marking. They are the second most common 3D laser marking materials.

Company News

Company News