- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

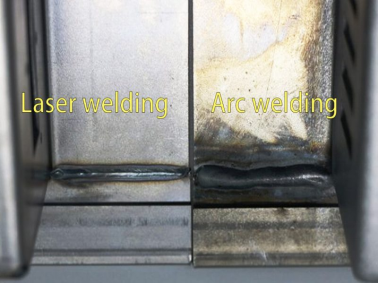

Why Top Manufacturers Are Switching to Laser Welding: 5 Key Benefits Over Traditional Welding Methods!

As industries demand faster production cycles, higher precision, and lower operational costs, laser welding machines are rapidly replacing conventional arc welding, TIG, and MIG systems. SanLaser, a pioneer in laser welding technology, explains why businesses worldwide are making the shift—and how it could transform your operations.

1.Precision Redefined: Eliminate Costly Rework

Traditional welding methods often struggle with heat distortion and inconsistent weld seams, leading to wasted materials and time-consuming rework. Laser welding delivers micron-level accuracy with minimal heat input, ideal for:

Aerospace components requiring flawless joints.

Medical device manufacturing where surface integrity is critical.

Electronics assembly for delicate circuit boards.

Case Study: A European automotive supplier reduced post-weld defects by 73% after adopting laser systems.

2.Speed + Efficiency = 40% Faster Production

Laser welding operates at up to 100 mm/s, outperforming TIG welding (5-10 mm/s) and MIG welding (20-50 mm/s). Its non-contact process eliminates electrode replacement downtime, enabling:

24/7 production with automated integration.

Energy savings of 30-50% compared to arc welding.

3.Versatility: Weld What Others Can’t

From reflective metals like aluminum and copper to dissimilar material bonding (e.g., steel to titanium), laser welding handles challenges that stump traditional methods. Advanced systems now offer:

Adjustable spot sizes (0.1mm–10mm) for thin foils or thick plates.

Gas-free welding options for cleaner outputs.

4. Long-Term Cost Savings: Debunking the "High Initial Cost" Myth

While laser welding machines may have higher upfront costs, they slash long-term expenses:

Lower labor costs: Reduced need for skilled welders.

Material savings: Near-zero spatter and 99% material utilization.

Maintenance: No consumables (e.g., electrodes, gas cylinders).

Did You Know? ROI is typically achieved within 12-18 months for SMEs.

5. Sustainability: Align with Global Green Standards

With tightening environmental regulations, laser welding provides:

Zero toxic fumes (vs. ozone/CO₂ emissions from arc welding).

Energy-efficient operation compliant with ISO 14001.

Recyclable materials thanks to contamination-free joints.

Why Choose SanLaser?

Independent production capabilities: All the machines are manufactured in the company giving the customer an assurance of the spare parts and the service needed

24/7 Global Support: On-site training and troubleshooting in 15+ languages.

Rich foreign trade experience: More than 10 years of experience in laser machine foreign trade

Get professional support now

Related product links

Welder News

Welder News