- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Working principle of fiber laser cutting machine!

The working principle of fiber laser cutting machine is both interesting and complicated. SAN LASER will show you how.

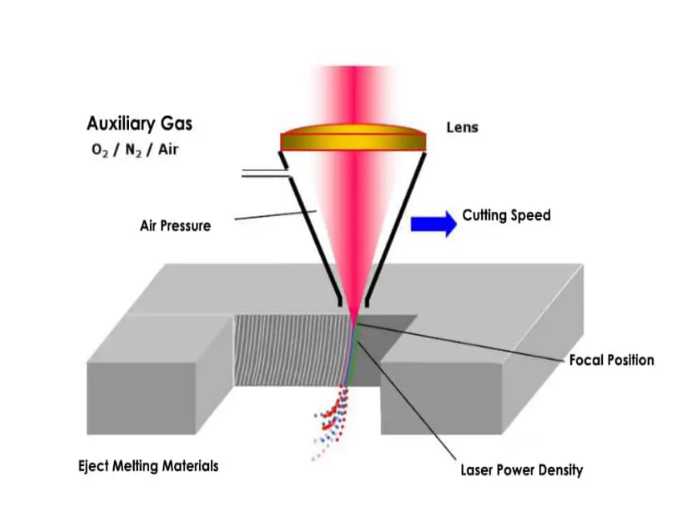

Laser cutting uses a laser beam as a heat source for thermal cutting, and its working principle is similar to laser welding. The temperature of laser cutting exceeds 11000℃, which will cause the material to vaporize. In addition to melting, vaporization also plays an important role in the cutting process. For some materials, such as carbon and ceramics, the laser cutting process is purely a vaporization process.

Metal laser cutting is mainly carried out using a high-power continuous carbon dioxide laser generator. During the cutting process, an inert gas stream is blown into the incision to smooth and straighten the molten metal. Adding an oxygen stream from the jet stream can increase the cutting speed.

Laser cutting has narrow incisions, precise dimensions, and smooth surfaces, and has better cutting quality than other thermal cutting methods. Most metal materials can be cut with lasers, and the cutting thickness ranges from a few microns to 50 mm.

Laser cutting equipment has a high investment, but it is mainly used for precision cutting of materials with a thickness of less than 12 mm, such as stainless steel, titanium, titanium alloys, refractory metals and precious metals. It can also be used to cut non-metallic materials such as plastics, wood, fabrics, graphite and ceramics. For example, the wood industry uses lasers to cut plywood and particleboard, while the clothing industry uses lasers to cut fabrics.

Laser cutting is also suitable for special purposes, such as stone support drilling and surgery, where the laser is used as a scalpel. The parameters of the laser beam, the performance and accuracy of the laser cutting machine, and the CNC system directly affect the efficiency and quality of laser cutting.

Cutter News

Cutter News