- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Advantages of mold repair laser welding machines in battery manufacturing industry

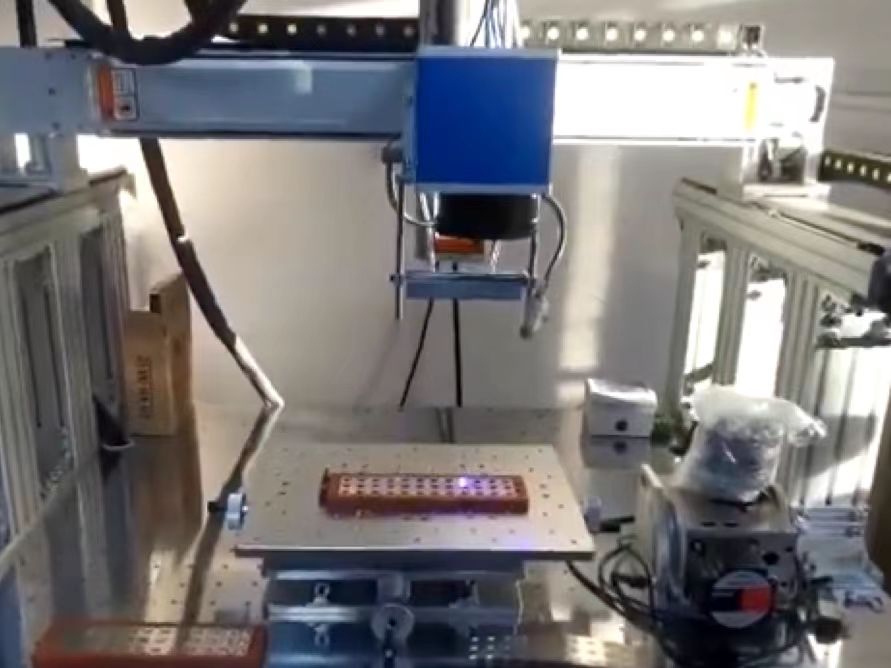

Galvanometer scanning laser welding machine is a frequently used laser welding solution. And it is suitable for the manufacture of many battery accessories. We have two major guarantees, SAN LASER laser production workshop and processing stability. Based on the high speed and flexibility of laser equipment, the manufacturing process depends on the performance of other mechanical parts in the system to achieve good welds.

This is a difficult task, considering the small size and high speed of the welds, as well as the huge number of welds that need to be completed in battery production. With the number of welds required in battery packaging, 6∑ grade weld quality is not enough. The solution to these major problems (process routing and weld quality assurance) is mostly obtained through high-speed image acquisition and analysis. Some of these methods have been tried in a few lower speed laser welding applications, but further improvements in speed and accuracy are needed to ensure the full potential of laser welding machines in battery manufacturing.

Traditional battery manufacturing technology can no longer meet the scope of battery applications in terms of battery effect and cost budget. The market now has higher requirements for battery application energy storage and battery life, and lower requirements for battery weight and cost. The challenges in the manufacturing process are still being solved. For the stability and quality assurance of laser welding machine processing batteries, please contact SAN LASER for more details

Related product links

Welder News

Welder News