- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Main considerations for aluminum laser welding!

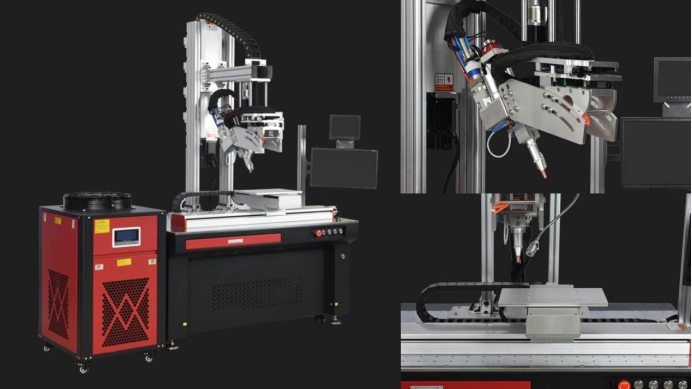

SAN LASER laser welding machine is a laser welding machine specially developed for welding aluminum and aluminum alloy materials. It has the characteristics of high energy density and high welding speed. It is a powerful tool for welding aluminum and its alloy materials. If aluminum and aluminum alloy products or accessories want to be welded firmly and have beautiful welds, they cannot be separated from aluminum alloy laser welding machines. Although the laser welding effect is good, aluminum and aluminum alloys have the characteristics of high reflection and low attraction rate, and welding is still technically difficult, so there are still a few points to pay attention to when laser welding.

When laser welding aluminum alloy, light reflection will appear on the surface of aluminum alloy, because aluminum alloy is a non-ferrous metal, which has strong reflectivity to various light. Aluminum alloy, a non-ferrous metal, has high reflectivity and low absorption rate for laser. Therefore, before welding aluminum alloy, it is necessary to clean the surface of aluminum alloy and remove the oil and other dirt on the surface. At the same time, in order to prevent oxidation from causing explosion and other safety threats during welding, it is also necessary to thoroughly clean the oxide film on the metal surface and completely remove the oxide film.

When using a laser welding machine to weld aluminum alloy, you must be fully prepared, because aluminum alloy is active and easily oxidized, and a large amount of dust and moisture are easily attached to its surface. Therefore, during the welding process, if you are not fully prepared, the things attached to the surface are easy to remain on the surface of the aluminum alloy with the rapid welding of the laser, thus affecting the quality of the aluminum alloy and the welding effect. All metals have thermal conductivity, so aluminum alloys also have strong thermal conductivity. When using laser welding, it is easy to reflect the laser or quickly transfer the heat of the laser away, which eventually leads to the failure of the welding of the aluminum alloy. Therefore, when laser welding aluminum alloy, you must pay strict attention and quickly increase the power density of the laser to prevent it from being reflected or conducted, and strive to weld the aluminum alloy with extremely high density at an extreme time, so as to avoid the occurrence of problems such as reflectivity.

Related product links

Welder News

Welder News