- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

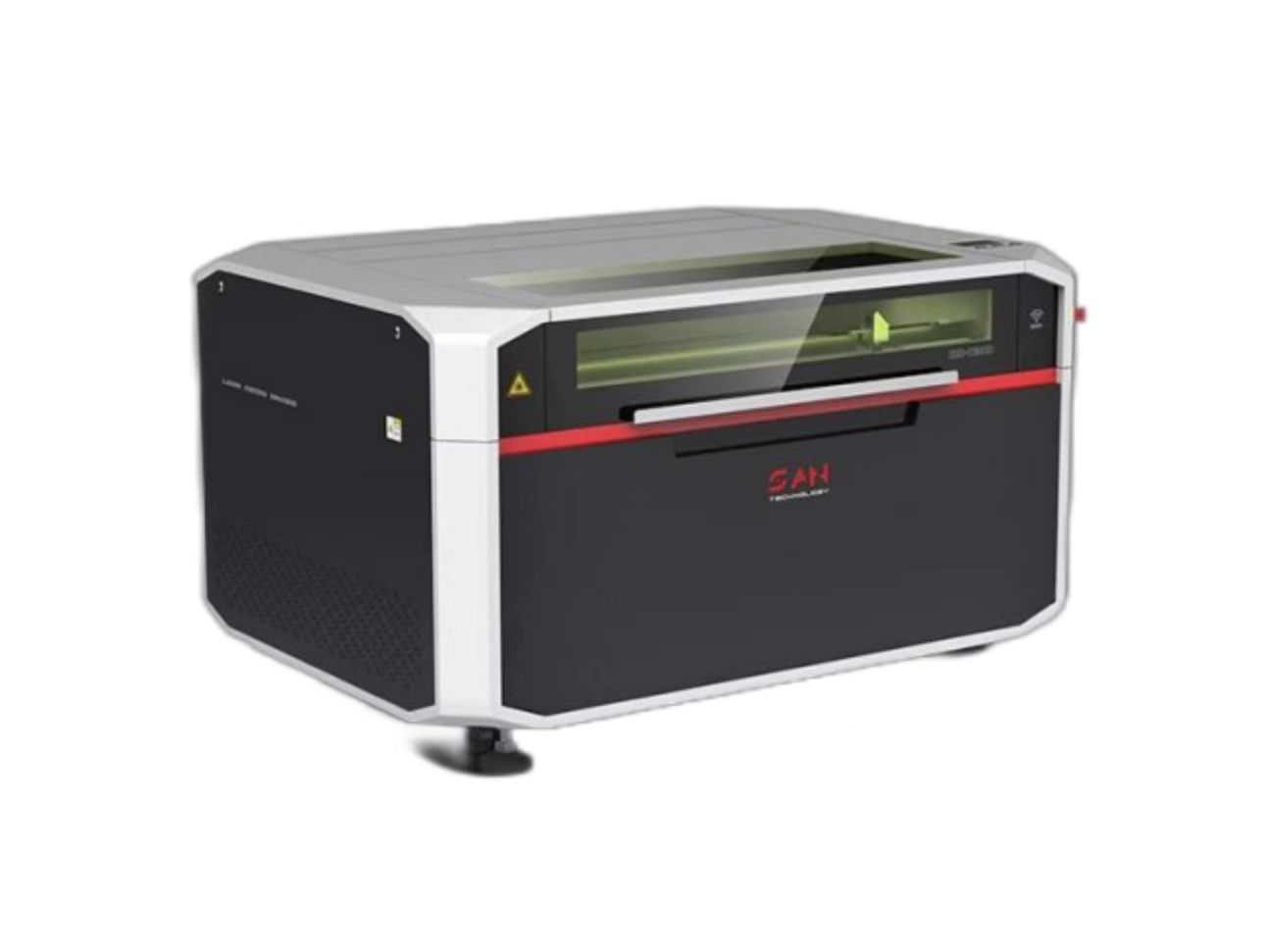

Application fields and equipment advantages of CO2 non-metal laser cutting machine!

CO2 non-metallic laser cutting machines have a wide range of applications, including but not limited to:

1. Cutting of wood, acrylic, glass, ceramics, plastic, rubber, paper and other materials.

2. Making signs, furniture, toys, watch lenses, etc.

3. Engraving and marking, such as engraving trademarks, personalized gifts, processing artworks, etc.

4. Processing of tiny parts, such as making molds, IPhone, computer parts, etc.

5. Reusing waste items, such as recycled plastic trinkets.

In terms of applicable materials, CO2 non-metallic laser cutting machines are suitable for cutting a variety of non-metallic materials, such as wood products, paper, leather, cloth, plexiglass, epoxy resin, acrylic, wool, plastic, rubber, tiles, crystal, jade, bamboo products, etc.

The equipment advantages of CO2 non-metallic laser cutting machine are as follows:

1. Efficient, stable and reliable cutting system: imported servo motor and guide bed transmission mechanism are adopted to ensure high-speed, stable and reliable cutting.

2. High precision, low cost and simple operation: high-precision and low-cost cutting head is adopted, which can easily achieve high-precision cutting.

3. Wide range of processing materials, advanced processing technology and strong flexibility: it can cut a variety of non-metallic materials, including wood, acrylic, PP, plexiglass, etc., and adopts advanced processing technology, which has the characteristics of strong flexibility and wide application range.

4. Energy saving and environmental protection, simple maintenance: adopt efficient fiber laser to reduce energy consumption and operating costs, and the equipment maintenance is simple, which reduces the maintenance cost.

5. High-tech, high-reliability and integrated design of electrical cabinet: adopt high-tech fiber laser and high-reliability electrical cabinet design to ensure the stability and durability of the equipment.

6. High cost performance and standardized after-sales service: provide cost-effective equipment, and standardized after-sales service to ensure the customer's experience and long-term reliability of the equipment.

7. High-end, beautiful, practical, and safe protection design: It adopts a high-end and atmospheric appearance design, which meets the aesthetic requirements of modern industrial production. At the same time, it has a safety protection design to ensure the safety of personnel and equipment.

8. Wide range of applications and low operating costs: It can be widely used in cutting, punching, engraving and other processing of various non-metallic materials, and has a low operating cost, saving production costs for customers.

Related product links

Cutter News

Cutter News