- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

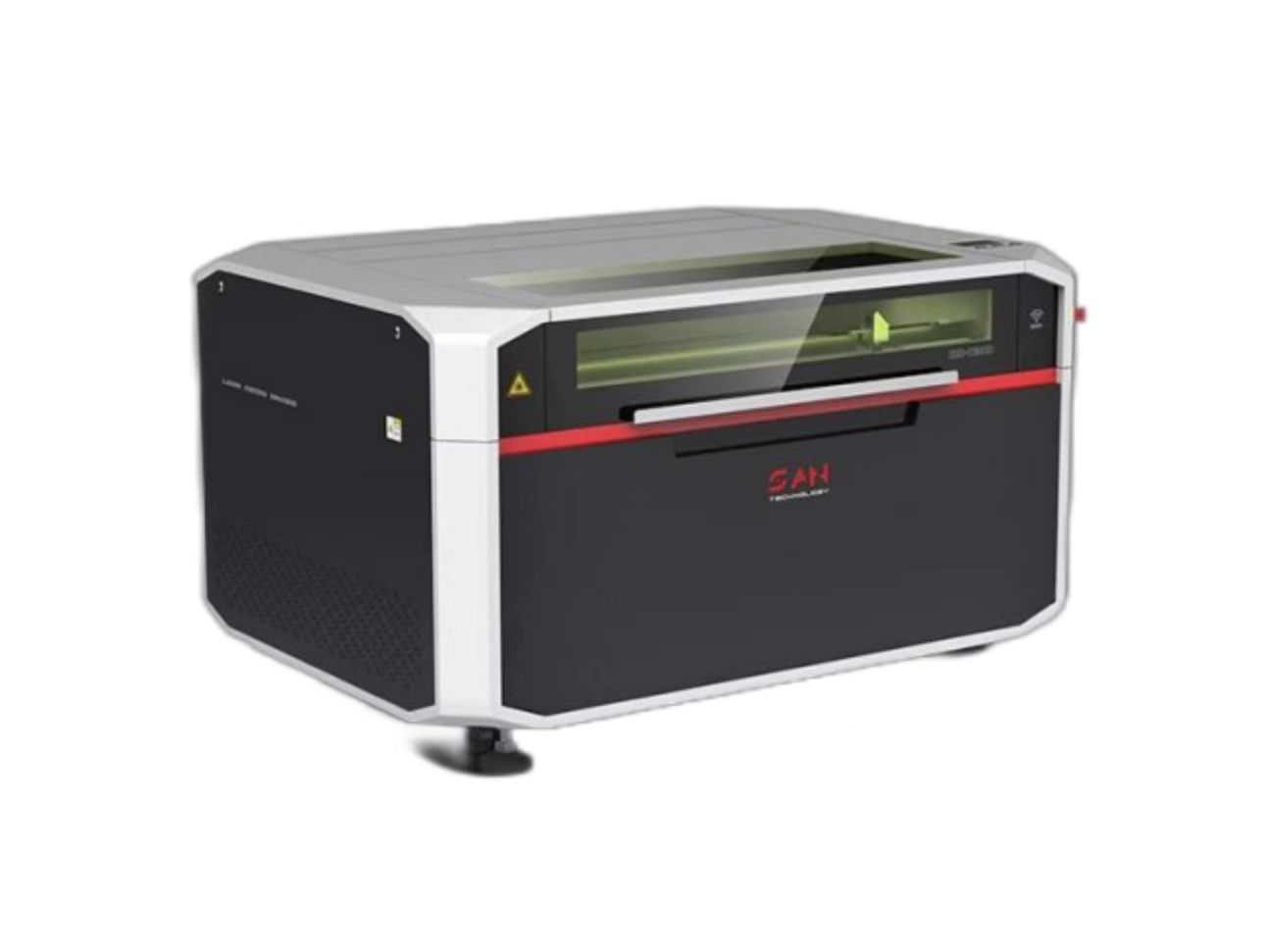

The Practical Application And Advantages Of Laser Cutting Machine In Sheet Metal Processing

(1) Use programming software to improve laser cutting efficiency. Laser cutting can effectively use the advantages of programming software, greatly improve the utilization rate of thin-plate materials, reduce the use and waste of materials, and reduce the labor intensity and strength of workers to achieve ideal results. On the other hand, optimizing this functionality of discharging can omit the cutting process of thin plate cutting, effectively reduce the clamping of materials and reduce the time of processing assistance. Therefore, it promotes a more reasonable arrangement of the cutting plan, which effectively improves the processing efficiency and material saving;

(2) Save product development cycle and realize mass production of sheet metal parts. In an increasingly developing market environment, the speed of product development means the market. The application of laser cutting machine can effectively reduce the number of molds used, save the development cycle of new products, and promote the speed and pace of its development. The quality of the parts after laser cutting is good, and the production efficiency is significantly improved, which is helpful for small batch production. It strongly guarantees the market atmosphere that the product development cycle is shortening day by day. The application of laser cutting can affect the size of the blanking die. Precise positioning of the size, laying a solid foundation for mass production in the future;

(3) Reduce sheet metal processing procedures and reduce production costs. In the sheet metal processing operation, almost all the plate parts need to be formed on the laser cutting machine at one time and directly welded and assembled. Therefore, the application of the laser cutting machine reduces the process and construction period, effectively improves the work efficiency, and can realize the workers The dual optimization and reduction of labor intensity and processing cost, while promoting the optimization of the work environment, greatly improving the speed and progress of research and development, reducing mold investment, and effectively reducing costs;

The effective life of laser cutting technology is long. At present, most of the plates with a thickness of more than 2 mm at home and abroad use laser cutting. In the market, laser cutting is commonly used to cut carbon steel plates within 20mm, stainless steel plates within 10mm, acrylic, wood and other non-metallic materials.

Laser cutting has the advantages of high level of flexibility, fast cutting speed, high consumption efficiency, and short product consumption cycle. It has quickly gained popularity in the consumer market. Compared with traditional cutting methods, laser cutting has the following characteristics:

★Laser cutting has high flexibility, fast cutting speed, high production efficiency and short product production cycle;

★Laser cutting has no cutting force and processing without deformation;

★No tool wear, good material adaptability, long effective life;

★Regardless of whether it is simple or complex sheet metal parts, it can be cut with laser precision and rapid forming at one time;

★It has narrow slit, good cutting quality, high degree of automation, easy operation, low labor intensity and no pollution;

★It can realize cutting and automatic layout and nesting, which improves the utilization rate of materials, has low production costs and good economic benefits.

Related product links

Cutter News

Cutter News