- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Application of laser welding in mold industry!

Molds play an extremely important role in modern industry, and their quality directly determines the quality of products. Improving the service life and precision of molds and shortening the manufacturing cycle of molds are technical problems that many companies urgently need to solve, but during the use of molds, failure forms such as collapse, deformation, wear, and even breakage often occur. Therefore, laser welding technology is also necessary for the repair of molds. The following introduces the application of laser welding in the mold industry.

A typical example of the application of laser welding in the mold industry is the mold repair laser welding machine. This equipment is easy to use for operators, can greatly improve the speed of welding, and the repair effect and precision are close to beauty, which makes the equipment widely used in the field of mold welding. The heat affected area of the repair welding of this welder is very small, and it has the advantages of not needing to heat in advance, and the welded workpiece will not anneal after work. This laser welding technology can not only be used for the repair of mold wear, but also can achieve precise welding of small and precise areas, and there will be no deformation or pores after repair. SanLaser has more than ten years of R&D and production experience, leading peers in technology and integration. Since its establishment, the company has always paid attention to the research and development of laser technology and the development needs of customers, and is committed to providing each enterprise with complete material processing solutions.

Mold laser welding repair method:

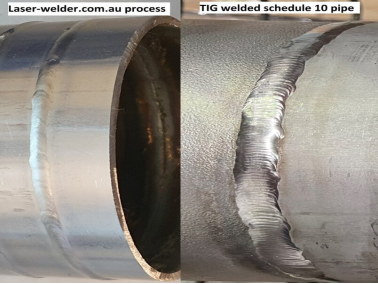

1. TIG welding repair uses the burning arc between the continuously fed welding wire and the workpiece as the heat source, and the gas sprayed from the welding torch nozzle protects the arc for welding. At present, argon arc welding is a commonly used method and can be applied to most major metals, including carbon steel and alloy steel. MIG welding is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloys. Due to its low price, it is widely used in mold repair welding, but it has disadvantages such as large heat affected area and large welding points. At present, it has been gradually replaced by laser welding in precision mold repair.

2. Laser cladding repair Laser welding is a welding method that uses a laser beam focused by a high-power coherent monochromatic photon flow as a heat source. This welding method usually includes continuous power laser welding and pulsed power laser welding. The advantage of laser welding is that it does not need to be carried out in a vacuum, but the disadvantage is that the penetration is not as strong as electron beam welding. Laser welding can perform precise energy control, so it can achieve the welding of precision devices. It can be applied to many metals, especially to solve the welding of some difficult-to-weld metals and dissimilar metals. It has been widely used in mold repair.

The mold laser welding machine is specially designed for the mold industry and is used to repair precision molds, such as digital products, mobile phones, toys, automobiles, motorcycles and other mold manufacturing industries. Through mold repair, the original mold can be fully utilized again, greatly saving

Related product links

Welder News

Welder News