- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

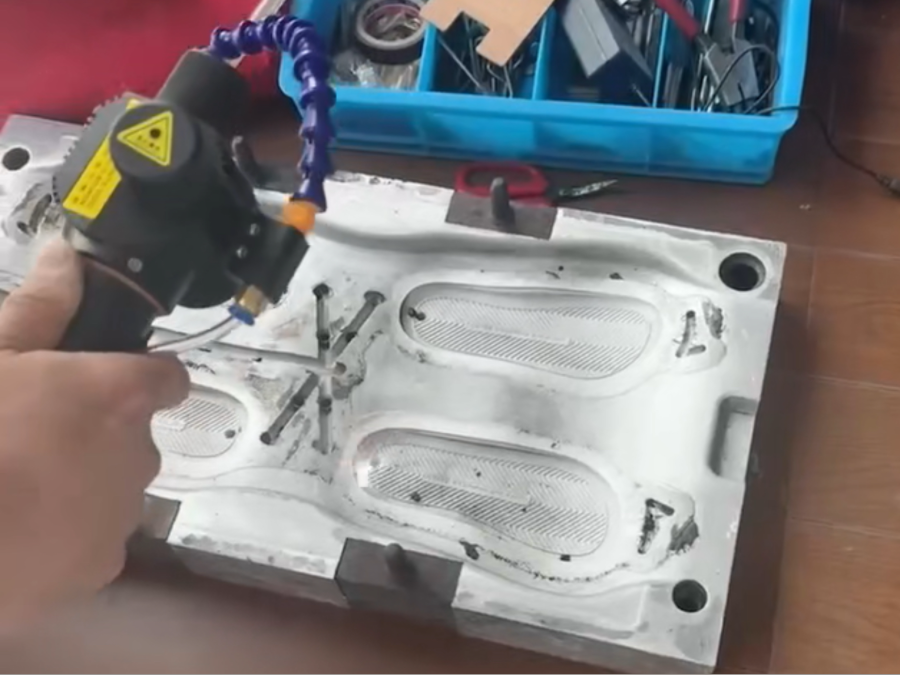

How to clean shoe molds, glass molds, rubber molds, etc.?

With the development of economy, a large number of rubber products have appeared in the market, and the molds for producing these rubber products are easily contaminated. To maintain normal precision, it is necessary to remove the dirt on the surface. Conventional cleaning methods cannot meet the needs of production. It is under this demand that laser technology is applied to mold cleaning, such as san-laser's laser cleaning machine.

Laser cleaning is a new type of industrial cleaning technology. It has the advantages of green environmental protection, high cleaning efficiency, and low labor intensity. It is a cleaning technology with great development potential and practical value. SAN analyzed the causes of surface contamination of rubber product molds and determined that the main adsorption force between the rubber particles on the mold surface and the matrix is the van der Waals force. The rubber particles adsorbed on the mold surface are removed by throwing away. SAN analyzed the mechanism of laser cleaning, established a heat conduction model for laser cleaning of rubber product molds, and solved the heat conduction equation using the finite difference method. SAN used ANSYS software to simulate the temperature distribution when the laser heat source cleaned the surface of the rubber product mold, and used ANSYS software to calculate the maximum temperature of the mold surface under different laser power densities. The linear equation between the power density and the maximum temperature of the mold surface was obtained through the obtained data, and the theoretical value of the damage threshold when the laser cleaned the mold was predicted to be 1611w/cm2. By calculating the adsorption force between the rubber particles and the mold surface and the sinking force during laser irradiation, it was found that the theoretical value of the cleaning threshold when the laser cleaned 5μm rubber particles was 500W/cm2, while the cleaning threshold of 1μm rubber particles was 610W/cm2.

SAN conducted an experimental study on the laser cleaning technology of rubber product molds. Through the experiment, the effects of laser power, defocus and scanning speed on the cleaning effect were determined, and the damage threshold and cleaning threshold during laser cleaning were determined. The damage threshold was 1590W/cm2, which is very close to the theoretical value calculated earlier. The cleaning threshold is 530.2W/cm2, which means that the particle radius is mainly between 1-5μm. After determining the cleaning threshold and damage threshold during laser cleaning through experiments, the practical application of laser cleaning technology for rubber product molds was studied. After using laser cleaning technology to clean seal molds, it is easy to see the advantages of laser cleaning technology. Laser cleaning will be the mainstream of mold cleaning in the future, and laser cleaning technology will definitely play an important role in the mold industry.

Related product links

Welder News

Welder News