- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Breaking through the three major technical difficulties of high-power laser cutting!

With its unparalleled advantages such as large cutting format, fast cutting speed, and ability to cut thicker plates, high-power laser cutting has been widely recognized by the market. However, since high-power laser cutting technology is still in the early stages of popularization, some operators are not very proficient in the skills of high-power laser cutting.

Through long-term testing and research, Chuangxin Laser's high-power laser cutting engineers have summarized a series of solutions to poor high-power laser cutting for reference by all colleagues in the industry.

If the cutting effect is found to be poor, the following reasons should be checked first:

1. All lenses in the laser head are not contaminated and are clean;

2. The water temperature of the water tank is normal, and there is no condensation on the laser;

3. The cutting gas purity is excellent, the gas path is smooth, and there is no leakage.

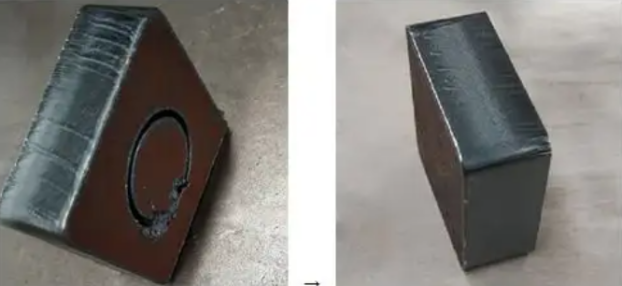

Problem 1: Cutting stripes

Possible reasons:

1. Incorrect nozzle selection, nozzle is too large;

2. Incorrect air pressure setting, too high air pressure causes overburning with stripes;

3. Incorrect cutting speed, too slow or too fast cutting speed will also cause full overburning.

Solution:

1. Replace the nozzle, replace the nozzle with a smaller diameter, for example, for 16mm carbon steel bright surface cutting, you can choose high-speed nozzle D1.4; for 20mm carbon steel bright surface, you can choose high-speed nozzle D1.6;

2. Reduce cutting air pressure to improve end face cutting quality;

3. Adjust the cutting speed, the power and cutting speed should be properly matched to achieve the effect shown in the right figure below.

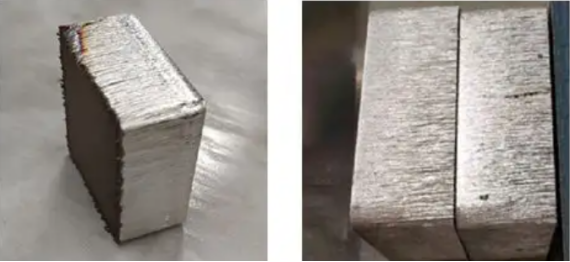

Problem 2: There is a slag on the bottom

Possible reasons:

1. The nozzle is too small and the cutting focus does not match;

2. The air pressure is too small or too large, and the cutting speed is too fast;

3. The material of the plate is poor, and the quality of the plate is poor. It is difficult to remove the slag with a small nozzle.

Solution:

1. Replace the nozzle with a larger diameter and adjust the positive focus to the appropriate position;

2. Increase or decrease the air pressure until the air flow is appropriate;

3. Choose a good plate.

Problem 3: There are burrs on the bottom

Possible reasons:

1. The nozzle diameter is too small to meet the processing requirements;

2. The negative defocus is not matched, the negative defocus should be increased and the appropriate position should be adjusted;

3. The air pressure is too low, resulting in burrs on the bottom and inability to fully cut.

Solution:

1. Use a large-diameter nozzle to increase the air flow;

2. Increase the negative defocus so that the cutting section reaches the bottom position;

3. Increase the air pressure to reduce the burrs on the bottom.

Related product links

Cutter News

Cutter News