- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

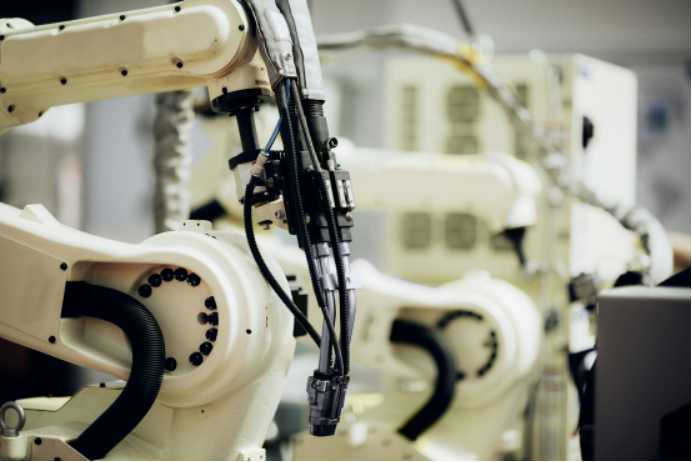

Comparison of the advantages and disadvantages of robot welding and traditional manual welding!

With the continuous advancement of technology, welding robots have gradually replaced traditional manual welding, which has brought many benefits to enterprises. I hope that through this article, everyone can have a deeper understanding of this magical world of welding.

1. High production efficiency

Industrial welding robots can perform fast and precise welding work without interruption, significantly improving production efficiency. However, traditional manual welding requires a lot of human resources, takes a long time, and has relatively low efficiency.

2. Reliable welding quality

The robot is small in size and light in weight, and is not limited by human physical strength. Moreover, due to its unique programming memory function, it can ensure that the parameters of each welding are exactly the same, thereby ensuring the stability and reliability of welding quality. On the contrary, manual welding is easily affected by human factors such as operating technical proficiency, physical and mental fatigue, and welding quality is not easy to guarantee.

3. High safety

Industrial welding robots work in potentially dangerous environments, greatly reducing the probability of worker injuries. In contrast, manual welding is likely to cause various accidental injuries.

4. Cost-effectiveness

Although the initial purchase cost of welding robots is high, from a long-term perspective, their excellent performance and stability have greatly reduced production costs. Traditional manual welding requires more manpower and time consumption, so the overall cost-effectiveness is low.

5. High level of automation

Industrial welding robots can complete welding tasks independently without too much human intervention, which can not only increase production speed but also ensure that product quality does not fluctuate too much. In contrast, traditional manual welding seems a bit backward, requiring workers to stay at their posts all the time, with heavy work and low efficiency.

In short, the process of industrialization has brought us great benefits. As one of the representatives, industrial welding robots will surely play an increasingly important role in the future. I believe that in the near future, we will see more welding robots active in factory workshops, creating a better, safer and more economical production environment for society.

Related product links

Welder News

Welder News