-

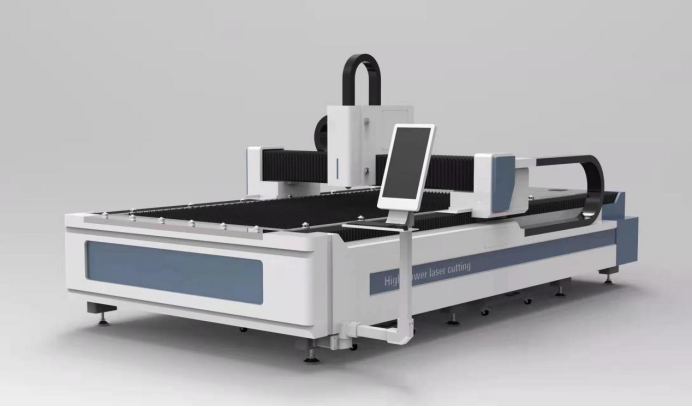

Causes and solutions for aging of fiber laser cutting machines

1. Parameter setting relatedThe factory parameters of the fiber laser cutting machine are pre-set. Due to the variety of plates to be processed, the manufacturer is open to users to adjust the parameters. Although the factory-set parameters have a margin, they are the o...May 31,2024Learn more -

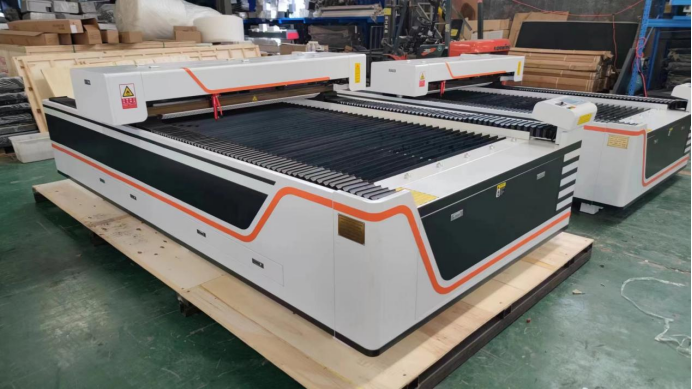

Sheet metal laser cutting machines: the experts of the industry!

Sheet metal laser cutters are workpiece cutting machines of modern manufacturing, playing a key role whether in construction, automotive manufacturing or aerospace. This article will delve into the principles, applications and future development of metal laser cutting machines.wo...May 30,2024Learn more -

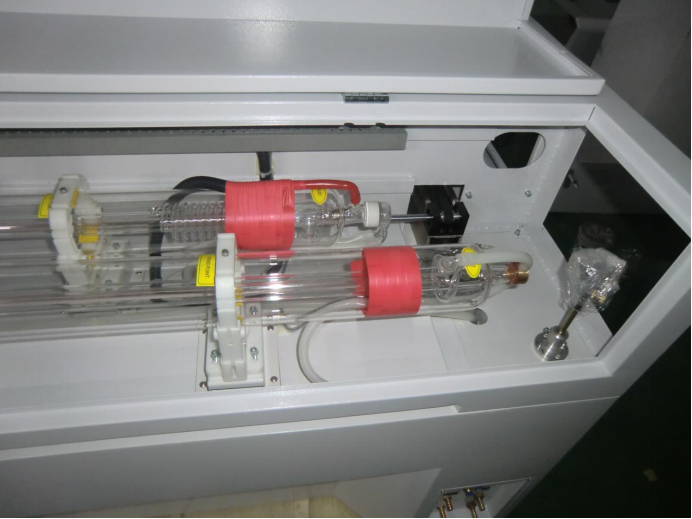

What is the difference between CO2 laser glass tube and metal tube?

1. SizeCO2 laser metal tube is more compact than CO2 laser glass tube; 2.LifespanCO2 laser metal tube has a longer life than CO2 laser glass tube. The former only needs to be ventilated, while the latter requires replacing the entire pipe. 3. Cooling methodCO2 laser RF ...May 30,2024Learn more -

How high can the precision of laser precision cutting be?In what industries are it mainly used?

Laser precision cutting is one of the most accurate, fastest and best quality precision cutting methods. Whether it is fiber laser for cutting metal, or CO2 and ultraviolet laser for cutting non-metallic materials, it can achieve precision processing of about 0.01~0.05mm, which h...May 30,2024Learn more -

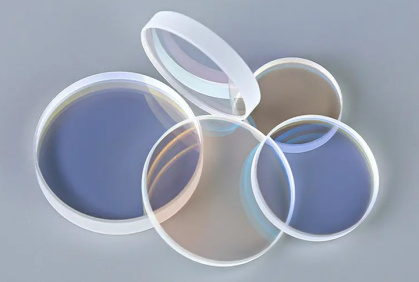

Method to locate the focus position of CO2 laser cutting machine!

Use a piece of flat and smooth white cardboard, lay it flat on the workbench, set the laser cutting head above it, and the height of the focusing lens from the cardboard is 10mm smaller than the focal length of the focusing lens. For example, if the focal length of the focusing l...May 29,2024Learn more -

The main components and functions of the CO2 laser cutting machine

The main components and functions of the CO2 laser cutting machine:1.CO2 laser tube: the main energy source, also called laser generator. It is distinguished by the size of the laser power. Generally, the power is 40W/60W/80W/100W/120W/150W/180W/200W, etc. The greater the power, ...May 28,2024Learn more -

How to maintain a laser cutting machine to prevent machine performance degradation?

Laser cutting machines will face loss problems in long-term use. Machine wear will affect cutting speed, cutting accuracy and cutting effect. The following are the problems and countermeasures that may occur when using laser cutting machines:1. Long-term use will cause the laser ...May 28,2024Learn more -

Eight main parameters of laser cutting machine!

The working principle of the laser cutting machine is to release energy when the laser beam is irradiated onto the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. The laser cutting machine has the characteristics of sa...May 28,2024Learn more -

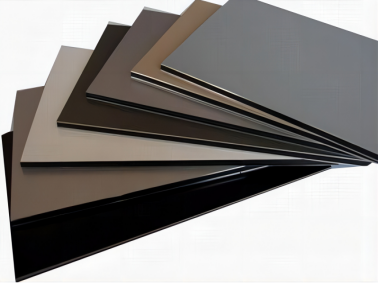

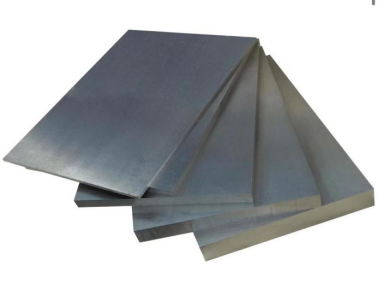

Essential for cutting carbon steel materials—fiber laser cutting machine!

Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. Theoretically, the higher the carbon content in carbon steel, the greater the hardness, the higher the strength, and the lower the plasticity. So what are the advantages of fiber laser cutting ma...May 27,2024Learn more -

Why are the protective lenses often burned when using laser welding machines?

The protective lens of the laser welding machine is consumable, so it needs to be replaced regularly. However, due to the influence of the process/technique/setup, etc., it may cause damage by slag retrieval. In rare cases, abnormal laser light output and other factors may a...May 24,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Cutter News

Cutter News