-

What projects can be created with a CO2 laser cutting machine?

CO2 laser cutting machine is a CNC laser machine that uses CO2 laser technology to cut and engrave materials. A CO2 laser cutting machine uses a carbon dioxide gas mixture to produce a high-powered laser beam, which is enhanced and focused by a series of mirrors and lenses to con...Jul 03,2024Learn more -

How to choose a suitable CO2 laser cutting machine?

CO2 laser cutting machines offer high precision, versatility, and speed, making them ideal for a wide range of cutting and engraving applications on a variety of materials. They are used across a wide range of industries, including manufacturing, signage, woodworking, and more. I...Jul 03,2024Learn more -

Application of laser cutting plastic technology

The laser cutting machine focuses the laser emitted from the laser into a high power density laser beam through the optical path system. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, thereby achieving the purpose of cuttin...Jul 03,2024Learn more -

Common sense of fiber laser cutting machine lens maintenance

The focusing lens of the fiber laser cutting machine is a relatively precise optical component, and its cleanliness directly affects the processing performance and quality of the laser cutting machine brand. Therefore, it is very necessary to maintain the focusing lens regularly....Jun 27,2024Learn more -

How to delay the aging speed of fiber laser cutting machine?

With the development of social productivity, the role of fiber laser cutting machine brands is becoming more and more important, bringing development opportunities to all walks of life. Helping users improve production efficiency, improve product quality, reduce production c...Jun 27,2024Learn more -

Annealing process principle of fiber laser cutting machine!

The laser cutting process and its fiber laser cutting machine equipment are being understood and recognized by many metal sheet laser processing companies. The equipment has gradually replaced traditional metal sheet laser processing methods such as plasma cutting machine, w...Jun 27,2024Learn more -

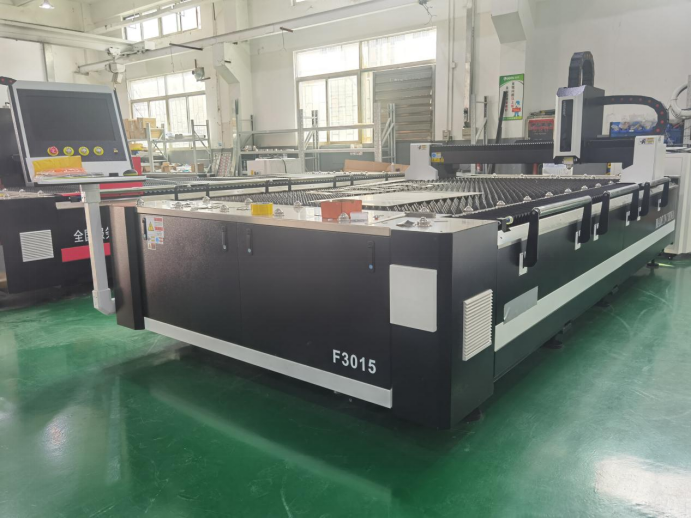

Working principle of fiber laser cutting machine!

The working principle of fiber laser cutting machine is both interesting and complicated. SAN LASER will show you how.Laser cutting uses a laser beam as a heat source for thermal cutting, and its working principle is similar to laser welding. The temperature of laser cutting exce...Jun 21,2024Learn more -

How to choose laser power for fiber laser cutting machine?

Fiber laser cutting machine has outstanding advantages in sheet metal cutting. It relies on the high temperature melting generated by laser to irradiate the surface of metal sheet and achieves the purpose of cutting through numerical control displacement. The advantages of laser ...Jun 19,2024Learn more -

Development trend of professional laser tube cutting machine

With the maturity and rapid development of laser technology, it has begun to be widely used in many industries. Laser cutting technology has also developed from plate cutting to metal pipe cutting. The birth and application of professional laser tube cutting machines have greatly...Jun 19,2024Learn more -

Considerations for selecting laser cutting machine power

With the development of the laser industry, more and more people choose laser cutting machines to cut materials. So what should you pay attention to when choosing the power of a laser cutting machine? Let's discuss it with SAN LASER.1. Cutting speed: Higher-powered lasers can...Jun 17,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Cutter News

Cutter News