- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

How to choose a suitable CO2 laser cutting machine?

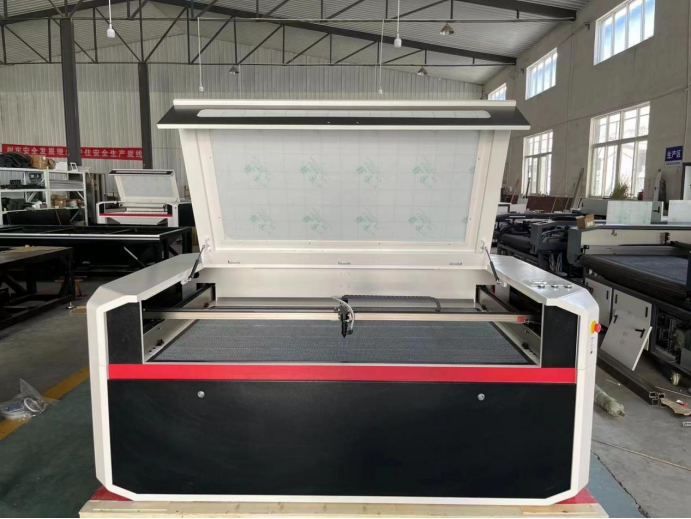

CO2 laser cutting machines offer high precision, versatility, and speed, making them ideal for a wide range of cutting and engraving applications on a variety of materials. They are used across a wide range of industries, including manufacturing, signage, woodworking, and more. If you are considering purchasing a CO2 laser cutting machine, there are a few things you need to know to ensure you choose the right machine for your needs.

Factors to Consider When Choosing a CO2 Laser Cutter

1. Laser Power: One of the most important factors to consider when purchasing a CO2 laser cutter is the power of the laser. The power of the laser determines how fast the machine can cut through material and how thick it can cut it, with higher powered lasers being able to cut thicker materials faster than lower powered lasers. However, higher powered lasers also tend to be more expensive. When choosing laser power, it is important to consider your needs to ensure that the machine you choose can handle the type of material you need to cut.

2. Material Compatibility: Consider the type of materials you will be using. CO2 laser machines can cut and engrave a wide variety of materials, including wood, acrylic, plastic, leather, fabric, and certain metals. Make sure the machine you choose is compatible with the materials you intend to use.

3. Cutting Accuracy: The accuracy of the machine is also an important factor to consider when choosing a CO2 laser cutter. The accuracy of the machine will determine how precise the cuts can be and how well the machine can handle complex designs. Machines with higher accuracy ratings tend to be more expensive, but may be necessary for certain applications.

4. Machine Size: Another factor to consider when choosing a CO2 laser cutter is the size of the machine. The size of the machine will determine the maximum size of material that can be cut, and it is important to choose a machine that is large enough to accommodate the material you need to cut. However, larger machines tend to be more expensive than smaller ones, so it is important to find a balance between size and cost.

5. Ease of Maintenance: It is also important to consider the maintenance requirements of a CO2 laser cutting machine. Regular maintenance is required to ensure that the machine remains in good working order and continues to operate at peak performance. Some machines may require more maintenance than others, so it is important to choose a machine that is easy to maintain and has easily replaceable parts.

6. Cost and Budget: Finally, it is also important to consider the cost of the machine. CO2 laser cutting machines can range in price from a few thousand dollars to tens of thousands of dollars, depending on the size, power, and features of the machine. It is important to consider your budget when choosing a machine, but it is also important to consider the long-term benefits and potential cost savings that can be achieved through increased efficiency and productivity.

CO2 laser cutting machines are versatile and powerful tools that can be used in a wide variety of industries. By carefully considering these factors and conducting in-depth research, you can select a CO2 laser cutting machine that will best suit your needs and help you achieve the results you want.

Cutter News

Cutter News