- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What projects can be created with a CO2 laser cutting machine?

CO2 laser cutting machine is a CNC laser machine that uses CO2 laser technology to cut and engrave materials. A CO2 laser cutting machine uses a carbon dioxide gas mixture to produce a high-powered laser beam, which is enhanced and focused by a series of mirrors and lenses to concentrate its energy into a coherent and powerful beam. The focused laser beam is directed onto the material to be cut, and the high energy density of the laser heats, melts, or vaporizes the material at the point of contact. As the laser beam passes through the material, it cuts through or removes the material layer by layer to form the desired shape or pattern. The machine's computer control system precisely guides the movement of the laser beam, allowing for complex and precise cutting according to programmed designs.

CO2 laser cutting machines are used on a wide range of materials, including metals, plastics, wood, and more, offering high precision and versatility in industrial and manufacturing applications.

CO2 Laser Cutting Machine Applications

CO2 laser cutters are very versatile and can be used to create a variety of projects on different materials. Some common projects include:

· Acrylic Signs and Displays: Precision cutting allows the creation of intricate custom acrylic signs, logos, and displays.

· Woodworking Projects: CO2 lasers can cut and engrave wood, making them suitable for creating intricate wood patterns, ornaments, puzzles, and personalized wood products.

· Metal Fabrication: While CO2 lasers are not as common as fiber lasers for metal cutting, they can still be used for thin sheet metal to create metal signs, jewelry, and decorative pieces.

· Leather Products: CO2 laser cutting of leather can create precise patterns for items such as wallets, belts, and custom leather accessories.

· Paper and Cardboard Crafts: CO2 lasers are ideal for intricate paper cutting and engraving, making them suitable for card making, invitations, and art paper crafts.

· Textiles and Fabric Cutting: Custom textile designs, fabric patterns, and intricate clothing cutting can be achieved with a CO2 laser cutter.

· Rubber Stamps: High-precision cutting and engraving can create detailed custom rubber stamps for a variety of applications.

· Packaging Prototyping: CO2 lasers can be used to create prototypes of packaging designs, allowing for rapid testing and iteration of different packaging concepts.

· Model Making: Architectural models, prototypes, and hobbyist projects benefit from the precision and versatility of CO2 laser cutting.

· Educational Projects: CO2 laser cutters are used in educational settings for students to create science projects, artistic designs, and a variety of prototypes.

· These examples demonstrate the wide range of projects that can be accomplished with a CO2 laser cutter, making it a valuable tool for industries such as manufacturing, craft, design, and education.

When do you need to choose a CO2 laser cutting machine?

When considering choosing a CO2 laser cutting machine, consider the complexity and diversity of your cutting needs. CO2 laser cutting machines are particularly beneficial for projects that require precision and versatility in a variety of materials. Choose a CO2 laser cutting machine when:

1. Material Diversity: If your project involves cutting a range of materials such as wood, acrylic, leather, paper, and certain metals (especially thin sheets), the versatility of CO2 lasers makes it an excellent choice.

2. Intricate Designs: CO2 laser cutting machines excel at creating detailed and complex designs. If your application requires fine details, sharp edges, and intricate patterns, it can provide the precision required for these tasks.

3. Engraving Capabilities: CO2 lasers are not only used for cutting, they also excel at engraving. If your project involves adding personalized or decorative engravings to materials, CO2 lasers can provide a comprehensive solution.

4. Non-Metallic Materials: While fiber lasers are generally preferred for metal cutting, CO2 lasers are well suited for non-metallic materials. If your focus is wood, acrylic, plastic, fabric, or other similar materials, then a CO2 laser cutting machine is a practical choice.

In conclusion, when you need a versatile, precise, and cost-effective tool to handle a wide range of materials and complex designs, choose a CO2 laser cutter. Whether you are a hobbyist, educator, or involved in small-scale production, they can provide a balanced solution for a variety of cutting and engraving needs.

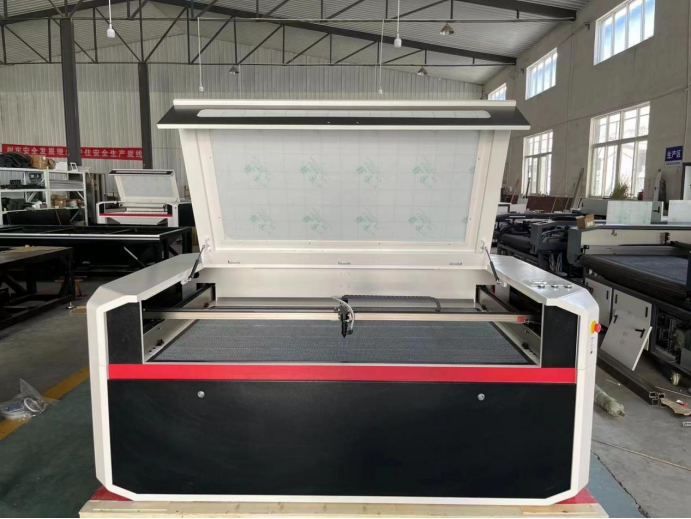

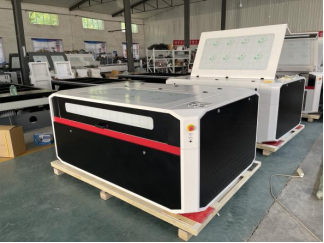

SAN LASER mainly produces a variety of laser machines. We can customize the machine according to your requirements. If you are interested in purchasing one, please contact us for a quote!

Cutter News

Cutter News