- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Cypcut Software: Best Laser Software for Fiber Metal Cutting!

The fiber laser cutting software you choose has a significant impact on your final product. As a laser cutting machine user, you interact with the software a lot before the machine makes its first cut, so you want a program that enhances your experience while getting the job done.

What to Look for in Laser Cutting Software

Laser cutting software is evolving rapidly, and there are many types to choose from. Simply searching the internet for the best program can yield a dizzying array of results. Fortunately, you can narrow down your choices by asking a few basic questions:

· Is it easy to use? There is always a learning curve when implementing any new software program. However, an overly complex program can muddy the process and affect the quality of the final product.

· Does it have CAD, CAM, and control capabilities? CAD (computer-aided design) software has an interface where you can create or upload your design. CAM (computer-aided manufacturing) programs encode the drawing so that the laser cutter can understand it. Control software communicates between the computer and the machine. All three of these capabilities are necessary to use a laser cutter. Ideally, a program will have all three so you don't have to buy additional applications.

· Does it get the most out of your materials? The materials used in laser cutting can be expensive and inconvenient to source. A program that helps get the most out of each workpiece can save you a ton of time and money.

· Does it facilitate fast cutting? The maximum speed at which a machine can operate is entirely dependent on the hardware capabilities. However, the right software can make the process more efficient, saving time on your projects.

· Is it compatible with your machine? If the software cannot communicate with your fiber laser cutting machine, then it is essentially useless.

Introduction: Cypcut Software

Cypcut is a laser cutting and nesting software that automates the highly technical CNC (computer numerical control) operations required for metal fabrication. One of the reasons Cypcut has become a popular metal cutting software is that it combines the functionality of CAD, CAM, and control tools into a single product.

How to use Cypcut software

Click this link to install Cypcut and connect to your SAN fiber laser cutting machine. Please note that your computer must have at least 4 GB of RAM and 2 USB ports with Windows 7 or higher operating system. Your monitor must have a VGA interface with a resolution of 1280 × 1024 or higher.

Features and Functionality

Cypcut’s user-friendly graphical interface allows you to easily draw and edit your designs. The software’s workpiece frame, nesting, and on-the-fly cutting features reduce cutting time and save material. In addition, Cypcut can be connected to SAN fiber laser cutting machines, giving you a lot of functionality with just one software package.

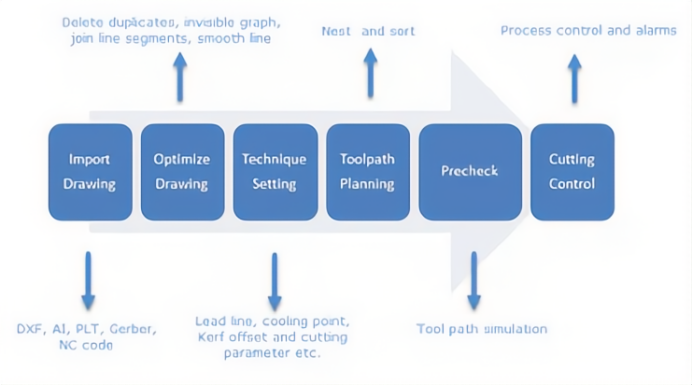

Cypcut's workflow improves efficiency through its logical sequence:

Controller

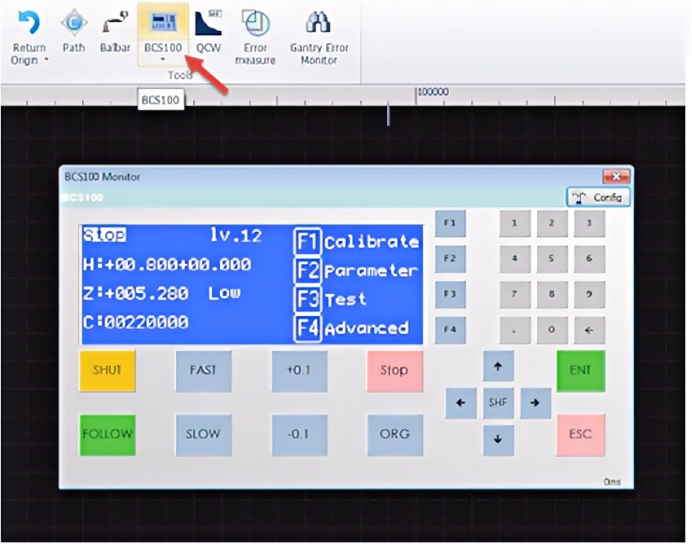

Cypcut's BCS100 controller features a simple user interface that helps you control the laser's height, working speed and slow speed, acceleration, origin setting, edge detection, and more. To maintain the integrity of the cut and protect the equipment, the controller includes an anti-collision function and vibration suppression.

User Interface

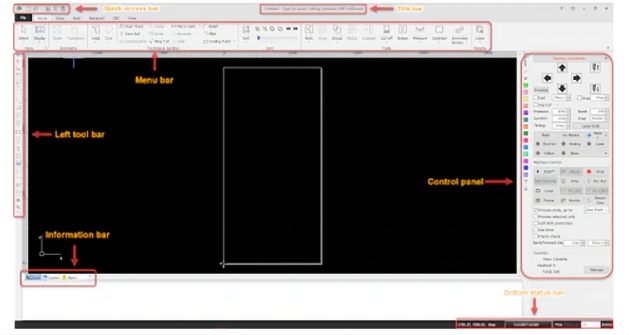

Cypcut software’s interface features easy-to-navigate drop-down menus, icons, toolbars, and a library of ribbons. Comprehensive design tools give you full control over your graphics, and convenient displays make accessing these tools fast and efficient. The software’s auto-optimization feature will automatically correct user errors, such as invisible shapes or lines and repetitions.

Nesting

Nesting refers to the technique of arranging design components in a way that reduces wasted space on the screen and on the workpiece. Laser nesting allows you to maximize material usage while reducing total project time. Nesting is widely used in metal fabrication, metal bending, and laser welding.

Nested cutting is a time-consuming operation for some software programs. These less-intuitive applications require the user to manually move design elements to find the best cutting position. With just a few clicks, Cypcut automatically nests your objects so you don't have to constantly drag items around the screen to find the best fit.

Fly Cutting

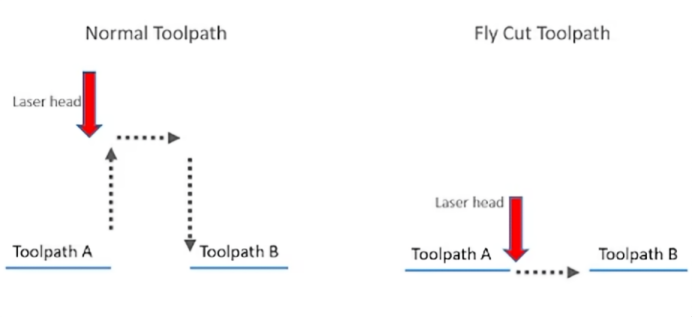

Fly cutting can save a lot of time in metalworking. When we use standard toolpaths, the laser automatically turns off as the laser head moves from one element to another, and then turns back on when it is time to resume cutting. However, when we use fly cutting, the laser stays on as the laser head moves.

As you might expect, fly cutting is a very complex technology function. In addition, software that supports fly cutting must also implement collision protection and path optimization to achieve fly cutting. Although not all software programs support fly cutting functions, Cypcut does. Using the fly cutting method, forging time is greatly reduced.

Compatibility

Cypcut software is fully compatible with all SAN LASER fiber laser metal cutting machines. Models in our range of cutting machines can be configured as standard, or we can customize a machine specifically to suit your metal cutting needs.

To give you the best possible start, we offer free installation and training when you purchase a machine. One of our dedicated, experienced technicians will come to your site to help you get your machine up and running, and train your team on the basics of setup, safety, maintenance and software.

Cutter News

Cutter News