- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

How to correctly reduce the loss of protective lenses?

1. Increase the air pressure appropriately. Under normal circumstances, the flow rate should not be less than 15, the pressure should not be less than 4, and it is recommended to use an oxygen pressure gauge of not less than 2 kg

2. When welding, try to weld the welding gun and the plate at 45°, not vertically;

3. Set the parameters as much as possible to give slow rise and fall, such as on/off gas delay 200-500ms, on/off light power 20%, on/off light gradual time 200-300ms, as shown in the figure, it cannot be set to 0;

4. When welding aluminum and galvanized plates, this material will damage the lens more easily than other materials, and the minimum power should be used for welding;

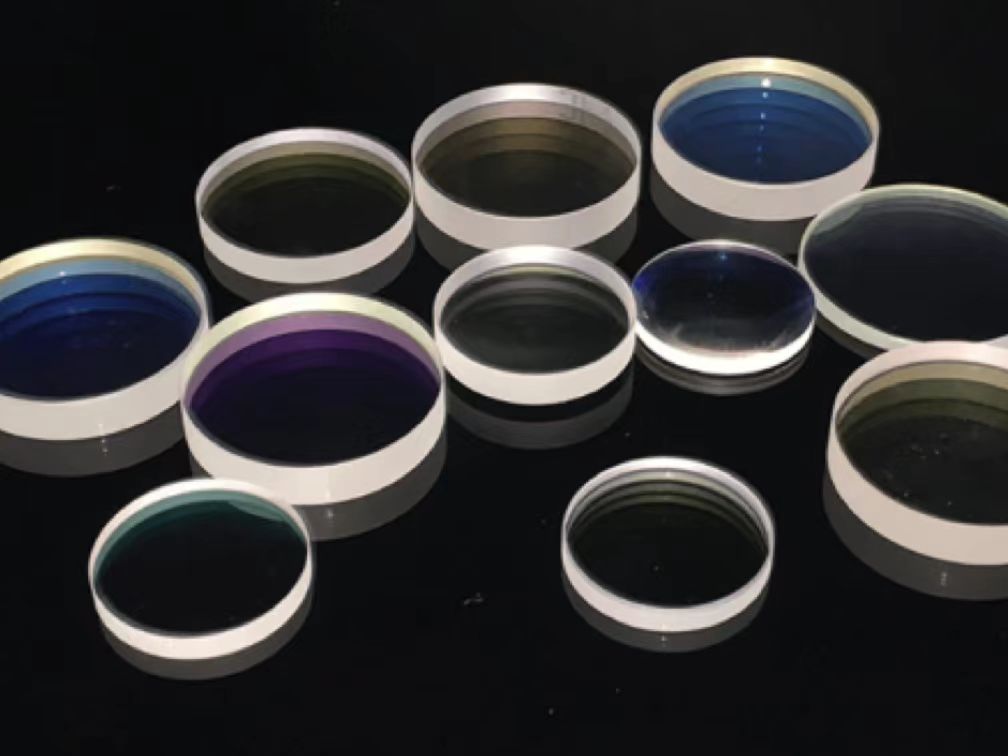

5. The quality of the protective lens also determines its durability. It is recommended to use the original lens;

6. Under high power, compared with low power, the loss of the lens will increase, which is an uncontrollable range;

7. When the above cannot be handled, the F200 focusing lens + extended wide scale tube can be replaced to reduce splashing.

The above is a brief introduction on how to reduce the loss of protective lenses for laser welding machines. Laser welding equipment often has minor faults during use due to improper operation or lack of regular maintenance. Therefore, it is recommended that customers receive professional training and perform daily maintenance on laser welding equipment when using it.

Related product links

Welder News

Welder News