- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

How to prolong the life of the protective lens of the handheld laser welding machine?

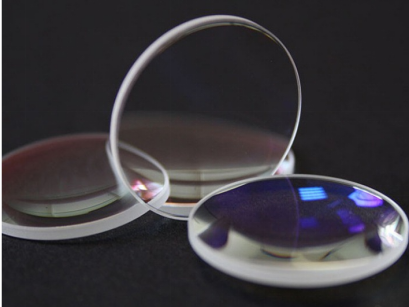

The protective lens of the handheld laser welding machine is a consumable, so it needs to be replaced regularly. However, due to factors such as process, technique, and setting, it may be damaged by slag. In some cases, abnormal laser light output may also easily cause the protective lens to be burned during the use of the handheld laser welding machine.

Therefore, in order to prevent the improper use of the handheld laser welding machine equipment, which may cause the protective lens to be burned frequently, we can extend the life of the laser welding machine protective lens from the following aspects.

1. First, consider whether the auxiliary gas we blow is pure. Whether the pressure meets the standard. If the air is blown, the quality of the compressed air needs to be checked, and an air purification, drying and filtering device needs to be configured.

2. Then, it is necessary to check whether the optical path is offset during the laser emission process, and whether other lenses are damaged during the operation.

3. Then, it is necessary to check whether the applicable nozzle aperture is too large.

4. Finally, check whether the software is reasonably configured for the timing of perforation-blowing.

Related product links

Welder News

Welder News