- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Laser Cutting and Engraving Introduction!

1. Introduction of Laser Cutting

laser cutting and laser engraving are becoming more popular these days, more people are doing experiments and business with laser engraving machines, applications and potential of laser cutters also booming.

We can do a lot of productive and profitable things with a single laser cutting machine, this tutorial explaining the essentials of laser cutting engraving business and product making ideas using a laser cutter, also included hot selling product making ideas using co2 laser cutters.

2.Basics of Laser Cutting

2.1 Laser Cutting Process

Laser Cutting is the process of cutting materials using a high power laser power source, generally, laser cutting is used for both industrial manufacturing and personal/small business applications.

Advantages of Laser Cutting:-

Laser cutting machines have lot of advantages compared to traditional cutting methods, it as follows

1.High Efficiency

2.High Speed

3.High-Quality Cutting

4.Non Contact Cutting

5.Material Flexibility

2.2 Laser Engraving

Laser Engraving, as well as Laser Etching, is the process of changing surface of a material using a laser machine for giving an individual design or personal touch, we can use the same machine for cutting and engraving but for metals separate machines are available for cutting and engraving.

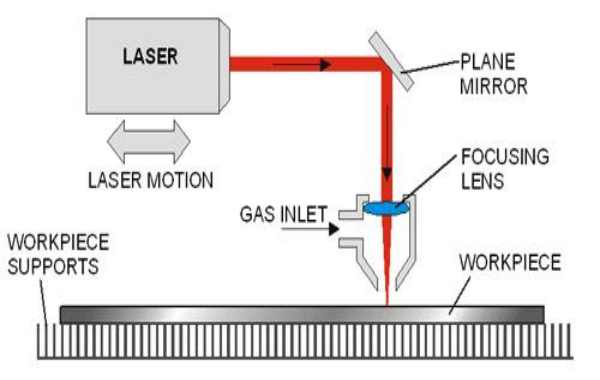

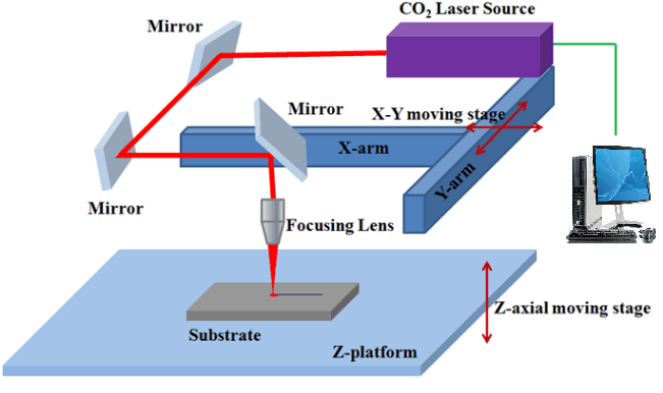

2.3 Laser Cutting Engraving Machine Working

Laser cutting machines are available in different mechanical and electrical configurations, here just showing a generic mechanical assembly of a laser cutting machine , It consist of

1.Laser Power Source

2.Reflecting Mirrors

3.Focus lens

4.X,Y,Z Actuation

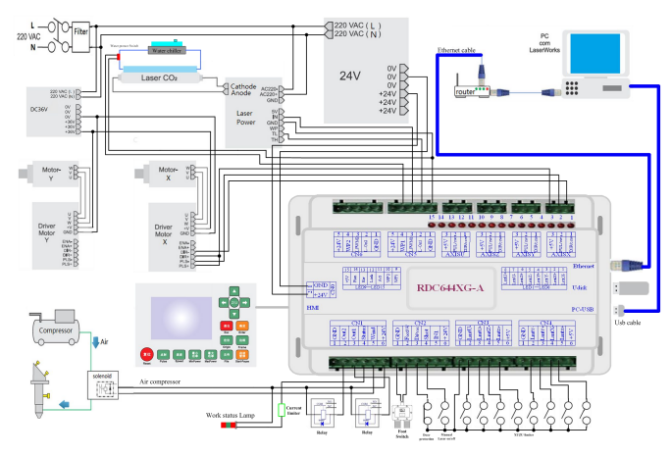

2.4 Electrical Diagram of Laser Cutting Machine

Electrical part of laser cutting is controlling the movements of x,y,z axes, laser power and other safety features by receiving commands from a computer. a software program from a computer is continuously sending commands to machine as G Codes, all the actuators and sensors are connected to the controller of the machine and all parameters controlled by reading instructions in G code which received from computer software through cable or wifi.

Cutter News

Cutter News