-

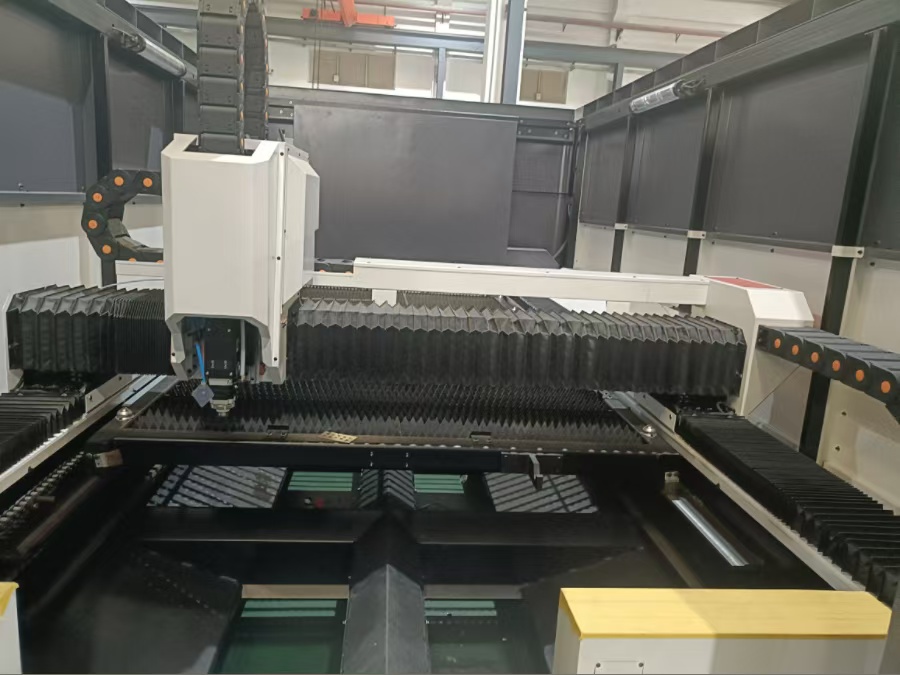

6020 12kw/20kw/30kw ready in stock ! 15 days shipping time !

Our company specializes in the production of Fiber laser cutting machines, the models are as follows:Fiber sheet cutting machine 3015 4015 4020 6020 6025 8025/ 1.5kw-30kwGround Rail cutting machine 13025 13030 14035 /12kw 20kw 30kwPipe cutting machine 6012 6016 6023 /1500w 2000w ...Feb 13,2025Learn more -

Laser cutting machine processing quality evaluation standard!

There is no unified standard for laser cutting quality evaluation in the world. The main basis for detecting laser cutting quality is JIS and WES (welding specifications). There are standardization issues about laser cutting in CEN (European Standardization Organization) and ISO ...Feb 13,2025Learn more -

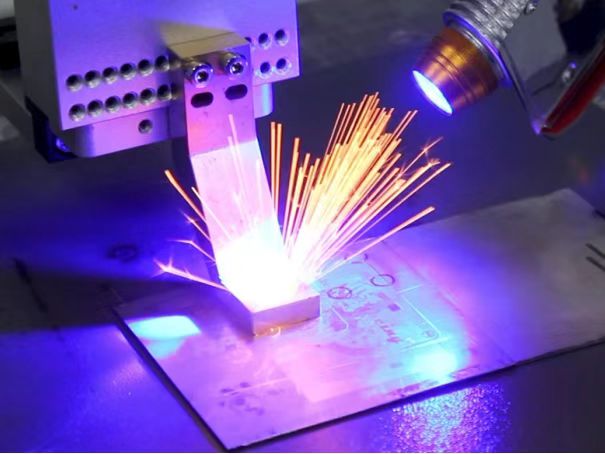

Battery Laser Welding for Battery Pack Manufacturing!

This battery laser welding machine is one of the best laser welding machines for battery backplanes. The machine is equipped with an articulated galvanometer system. Articulation means moving the laser gun on the X-axis and Y-axis. In this way, you can control the laser welding a...Feb 12,2025Learn more -

Why is laser paint removal safe?

As we all know, laser paint removal is a modern technology. It is the most effective and safest option currently available. There are many reasons why it is safe. In this section, we will tell you six reasons why laser paint removal is safe.Non-contact processLaser paint removal ...Feb 11,2025Learn more -

Application of pulse laser cleaning machine!

Application materials: Pulse laser cleaning machine can clean most metal and non-metal materials. Generally used for metal materials. For example, ordinary iron, copper, aluminum alloy, stainless steel, etc.Some metals come into contact with moisture and oxygen in the air, underg...Feb 11,2025Learn more -

What are the differences between the "three horses" in the field of laser processing?

It is said that laser welding, laser cutting and laser marking together constitute the "three horses" of laser processing technology and are widely used in the industrial field. Compared with laser cutting and laser marking, laser welding has a relatively short dev...Jan 23,2025Learn more -

Best Methods for Heavy Rust Removal:laser Rust Removal!

Heavy rust accumulation is a common problem that affects a wide range of materials, particularly metals. Rust can quickly degrade the integrity and appearance of items. Selecting the right rust removal method is crucial to preserving the material's quality and ensuring its lo...Jan 22,2025Learn more -

What are the benefits of buying a galvanometer laser welding machine?

Galvanometer laser welding machines are widely used in many industries. It can improve production efficiency and reduce costs. At the same time, it also provides a guarantee for product quality. If you have such equipment, it can bring the following benefitsEfficient production:T...Jan 22,2025Learn more -

Principle of laser cleaning!

In the mid-1980s, scientists such as Beklemyshev and Allrn combined laser technology with cleaning technology according to actual work needs and conducted relevant research. Since then, the technical concept of laser cleaning was born. It is well known that the binding force betw...Jan 21,2025Learn more -

Features of pulse laser cleaning machine!

1. High peak power:Pulse laser cleaning machine releases high energy in the form of short pulses, and can release high energy in a very short time, so it has a higher peak power. When performing laser cleaning tasks, not only can higher laser energy be used to remove oxide layers...Jan 21,2025Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News