-

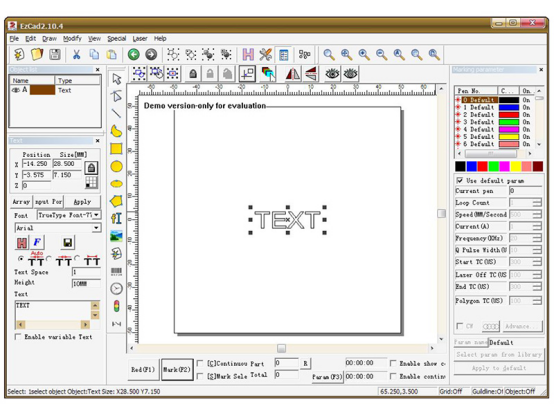

How To Install & Use EZCAD For Laser Marking Machine?

Definition What Is EZCAD? EZCAD is a smart software for Laser Marking System, which is used on 32 bit or 64 bit operating system of Windows XP, Windows 7, Windows 8 and Windows 10. EZCAD will drive the USB control board for laser marking machine to mark text, patterns, ...Mar 19,2025Learn more -

How to prevent the decline of cutting performance of fiber laser cutting machine?

With the development of laser cutting technology, fiber laser cutting machine has been widely used. In the process of use, we will also find some problems, such as reduced slicing speed and delicate cutting. It may be because of the fiber laser. The cutting machine causes loss du...Mar 13,2025Learn more -

How to find the focal position of the fiber laser cutting machine?

1. Focus on the surface of the plate This method also becomes 0 focal length. When using, select the cutting machine focus close to the workpiece surface. The smoothness of the upper and lower surfaces of the workpiece is different in this mode. Generally speaking, the cutti...Mar 13,2025Learn more -

Applications of lithium battery laser welding machine!

With the continuous development of modern science and technology, lithium batteries have gradually become one of the representatives of new energy. Its application in various fields is becoming more and more extensive. In the production process of lithium batteries, laser welding...Mar 10,2025Learn more -

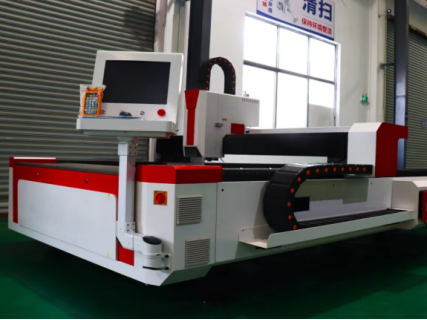

How to improve the working efficiency of fiber laser cutting machine?

Fiber laser cutting machine has six major characteristics: good cutting quality, fast cutting speed, high cutting accuracy, environmental protection and pollution-free, simple and convenient operation, and low processing cost. The power of fiber laser cutting machine produced by ...Mar 10,2025Learn more -

Oxygen vs. Nitrogen Laser Cutting-How to Choose!

When it comes to laser cutting, the choice of assist gas plays a crucial role in determining the quality and efficiency of the cut. Laser cutting offers significant advantages in terms of high precision and speed when processing metals such as aluminum, carbon steel, and sta...Mar 07,2025Learn more -

Bridge position (micro-connection) cutting process of fiber laser cutting machine!

The bridge position cutting process is to ensure that the parts and the plate are not separated during the cutting process and maintain the tiny connection points set in relative positions, so as to ensure the safety of the laser head during rapid movement. This process can autom...Mar 07,2025Learn more -

Laser Cutting for Construction!

Why Choose Laser Cutting for Construction?Flame cutting was once the primary method for processing steel plates thicker than 40mm, suitable for initial rough cutting needs. However, while this method has a lower initial investment, it has significant limitations: it often leads t...Mar 06,2025Learn more -

How To Use A Laser Cutting Machine for Beginners?

3 Tips You Should Know Before Starting a Laser Cutter. 1. Before starting, pay attention to check whether the power voltage matches the rated voltage of the laser cutting machine to avoid unnecessary damage.2. Check whether the exhaust pipe is placed at the air outlet to avo...Mar 06,2025Learn more -

What is laser cleaning and pulsed laser cleaning?

The laser in the laser cleaning machine has a specific wavelength. The high-energy beam of a specific wavelength is absorbed by media such as rust layers, paint layers, and contamination layers. Then a rapidly expanding plasma is formed. At the same time, shock waves, shock waves...Mar 05,2025Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News