-

Principle of laser cleaning!

In the mid-1980s, scientists such as Beklemyshev and Allrn combined laser technology with cleaning technology according to actual work needs and conducted relevant research. Since then, the technical concept of laser cleaning was born. It is well known that the binding force betw...Jan 21,2025Learn more -

Features of pulse laser cleaning machine!

1. High peak power:Pulse laser cleaning machine releases high energy in the form of short pulses, and can release high energy in a very short time, so it has a higher peak power. When performing laser cleaning tasks, not only can higher laser energy be used to remove oxide layers...Jan 21,2025Learn more -

Performance advantages of SAN LASER robot laser welding machine!

1. The robot laser welding machine does not require contact processing and has no external force on the welded parts. 2. The laser energy of the robot laser welding machine is highly concentrated, with small thermal impact and small thermal deformation. 3. The robot las...Jan 17,2025Learn more -

Maintenance tips for CO2 cutting machine laser and power supply!

Laser power supply is a high-performance automatic ignition constant current power supply, which is divided into two types: continuous laser power supply and pulse laser power supply. Below, the editor will introduce the maintenance methods of laser power supply and the maintenan...Jan 17,2025Learn more -

Advantages of jewelry YAG spot welding machine!

1. Energy, pulse width, frequency, spot size, etc. can be adjusted within a large range to achieve a variety of welding effects. Parameters are adjusted by the control rod in the closed cavity, which is simple and efficient; 2. Unique optical system design, stable optical pe...Jan 17,2025Learn more -

Main Differences: Continuous and Pulsed Laser Cleaners !

1. Output power intensityGenerally speaking, the greater the power of the laser cleaning machine, the higher the cleaning efficiency. The power range of the pulse laser cleaning machine is 200 watts to 1000 watts, and the power of the continuous laser cleaning machine is 1000 wat...Jan 16,2025Learn more -

Advantages galvanometer laser welding machine!

So what are the advantages of galvanometer laser welding machine compared with ordinary welding methods? Take a look at SAN LASER's galvanometer welding machine, it has the following advantages:1. High precision:Galvanometer technology can achieve high-precision laser welding...Jan 16,2025Learn more -

Difficulties in laser welding process!

At present, battery shells made of aluminum alloy materials account for more than 90% of the entire power battery. The difficulty of welding is that aluminum alloy has extremely high reflectivity to lasers, and is highly sensitive to pores during welding. Some problems and defect...Jan 15,2025Learn more -

Galvanometer laser welding machine application industry!

The galvanometer laser welding machine has the advantages of high efficiency and high precision. Therefore, it is widely used in many industries, including but not limited to the following fields:Automobile manufacturing industry:Such as automobile wheel hub, body welding, etc.El...Jan 15,2025Learn more -

Mold welding process and precautions!

In order to achieve the highest service life of the mold, the surface surfacing technology of flux-cored wire can obtain a thicker surface layer and a stable surface structure, which is easier to form a wear-resistant and heat-fatigue-resistant surface layer, saving materials and...Jan 13,2025Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

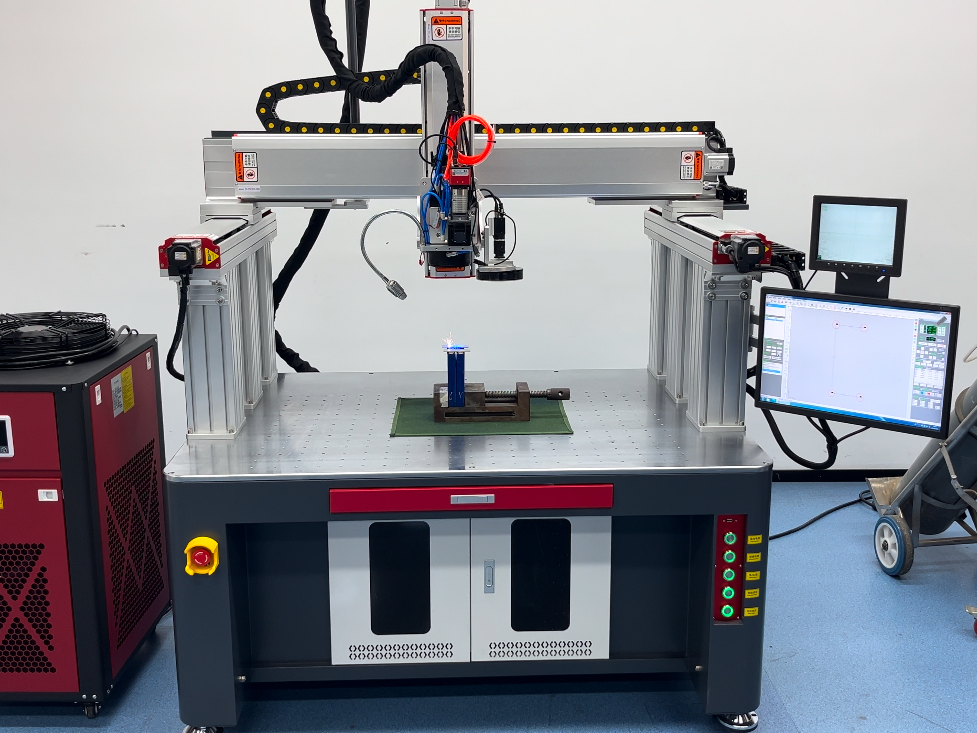

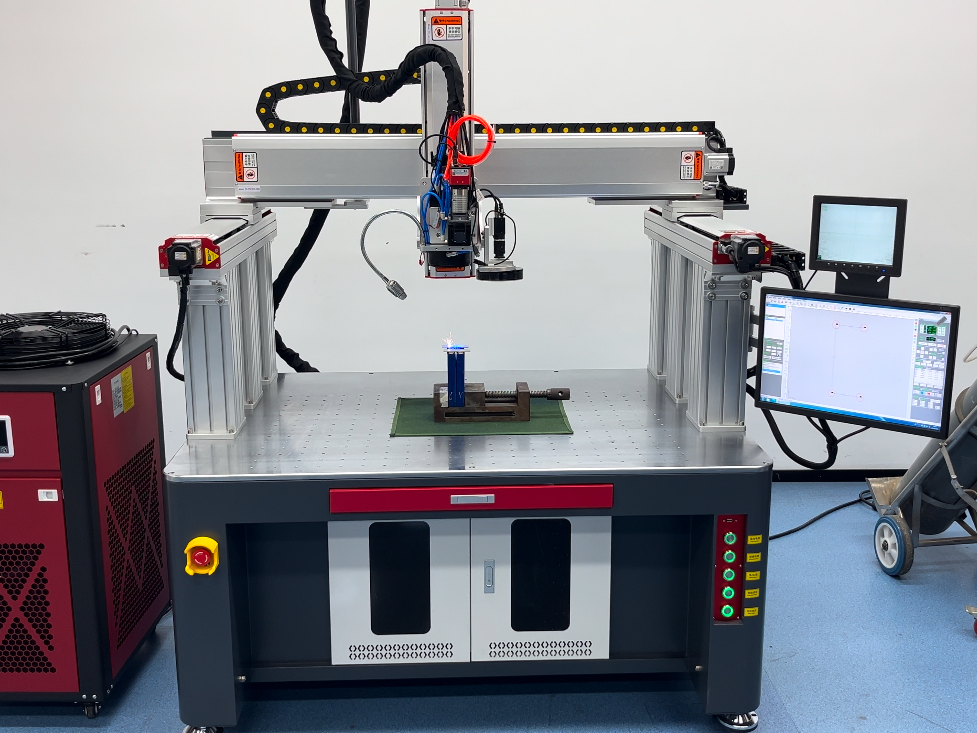

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News