- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Relationship between laser welding penetration and welding line energy!

Due to the presence of pores inside powder metallurgy materials, their bonding strength is much lower than that of smelting materials. Under the condition of ensuring welding penetration, the minimum line energy input must be used to reduce the welding heat affected zone.

Welding line energy is the energy per unit length of the laser acting on the welding direction, which is an important parameter for whether the energy is effectively used. The full penetration process conditions of laser deep penetration welding, the full penetration curve is related to the plate thickness. For thick plates, the stable deep penetration welding curve should include the full penetration curve. In order to study the influence of welding line energy on welding results, the relationship between the energy input per unit length of laser welding of Co powder materials (hereinafter referred to as line energy) and the melting depth is investigated. The welding line energy W (unit kj/cm) is defined as W=P/v

Where P is the incident laser power on the workpiece surface, and v is the welding speed.

The EFA51 CO2 laser and the f/5 focusing system were used to conduct experiments on pure Co sintered sample plates with thicknesses of 3 mm and 4 mm respectively. The plasma flame above the small hole is compressed by side-blown He gas, and the gas flow is at a 45o angle to the workpiece surface. The main blowing of argon gas protects the molten pool, and the back weld with uniform width on the back is regarded as a fully penetrated weld.

The heat input for full penetration welding is a function of both the laser power and the welding speed. When the laser power is constant, a welding speed with minimum heat input can be obtained. Similarly, when the welding speed is constant, a minimum heat input power can also be obtained. As the laser power and welding speed increase in a certain proportion, a narrow and deep weld can be obtained and the heat input decreases. As the welding speed decreases and the power increases, the weld penetration becomes shallower.

The laser power of the laser welding machine is taken as 0.8-1.3 kW, the welding speed and defocusing amount are adjusted, and the plate thickness is 3mm' to obtain full penetration, and a series of line energy under full penetration conditions are obtained. The results show that when the laser power is 1.2 kW, the line energy W has a minimum value, at which v=15 mm/s, W=0.8 kj/cm, and the depth-to-width ratio of the weld is the largest. Further experiments under the condition of 0.6 kj/cm line energy found that the weld penetration changes with the laser power. Under the same line energy input conditions, the weld penetration increases with the increase of laser power, while the weld width remains almost unchanged. Therefore, for the welding method based on the pinhole effect, increasing the laser power density has a more obvious effect on increasing the weld penetration than reducing the welding speed.

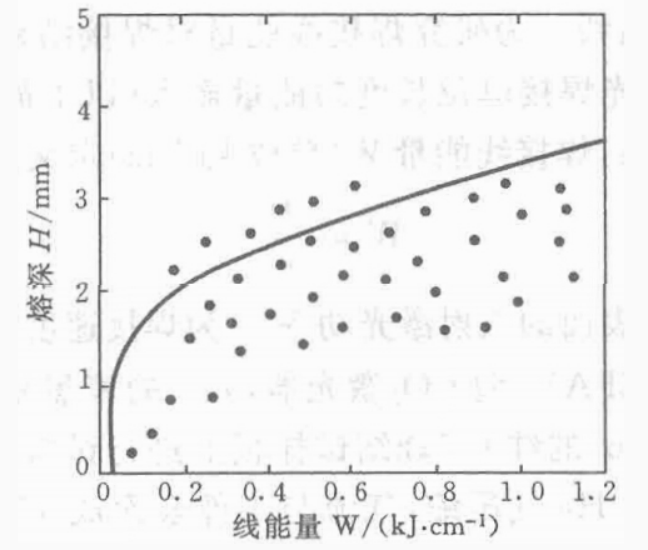

Scanning the weld on the surface of a 4 mm thick sample, it is found that there are several corresponding scattered points between the weld penetration and the line energy. The weld line energy envelope curve, that is, the curve of the minimum line energy, is shown in the figure. The mathematical expression of the envelope curve is obtained through calculation and analysis

H = -0. 32 + 3.6W0.25

Where, H is the welding penetration depth (mm), and W is the line energy (k/cm).

The data of a given parameter in an actual welding that falls on this curve can be considered to be a good parameter state. If the selected data is below the envelope curve in the figure, it can be considered that the energy utilization efficiency of this welding system is low, which requires analysis of whether it is caused by the laser transmission system or focusing system and other factors. It is worth noting that in most actual laser deep penetration welding, the selected data are slightly below the curve in the figure, but these welding parameters are still acceptable. For laser deep penetration welding, high power and high speed can improve the effective utilization of the laser, and the use of higher laser power can obtain a larger focus position range for stable deep penetration welding. Of course, this increase in laser power has a certain limit, because excessive laser power increases the absorption of laser by plasma, which reduces the depth of penetration. In fact, when the laser power is very small, a larger line energy can be obtained by reducing the welding speed.

Related product links

Welder News

Welder News