- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What are the precautions for laser cutting aluminum plates?

In modern manufacturing, laser cutting technology is widely used, including cutting of aluminum plates. However, this high-precision process also requires us to strictly abide by some operating specifications and safety precautions to ensure the quality and efficiency of cutting while protecting our work safety. This article will introduce the precautions for laser cutting aluminum plates in detail.

1. What are the precautions for laser cutting aluminum plates?

Choose the appropriate aluminum plate

For laser cutting, it is very important to choose a suitable aluminum plate. Generally speaking, pure aluminum plates have a high reflectivity and are not suitable for laser cutting; while alloy aluminum plates containing a certain proportion of other metal elements can provide better reflective performance and help improve the accuracy of laser cutting. In addition, it is also necessary to pay attention to whether the thickness of the aluminum plate meets the cutting range of the equipment.

2. Keep the equipment clean and maintained

After long-term use, the laser cutting equipment will affect its working efficiency and accuracy due to the influence of dust and oil. Therefore, we need to clean the equipment regularly, remove dust and oil to keep the equipment running normally. At the same time, it is also necessary to regularly check the various components of the equipment, such as the laser head, transmission system, etc., and replace damaged components in time to prevent failures.

3. Pay attention to safety protection

The laser cutting process will generate strong light and heat, and may even cause fire. Therefore, we must wear protective glasses and protective gloves during operation to avoid direct exposure to light and heat. In addition, the equipment will also generate noise and vibration during operation, which may cause harm to our body. Therefore, we need to wear non-slip shoes and earplugs to reduce the impact of noise and vibration.

In general, laser cutting of aluminum plates is a high-precision and high-efficiency process, but it also requires us to strictly abide by relevant operating specifications and safety precautions. Only in this way can we ensure the quality and efficiency of cutting while protecting our work safety.

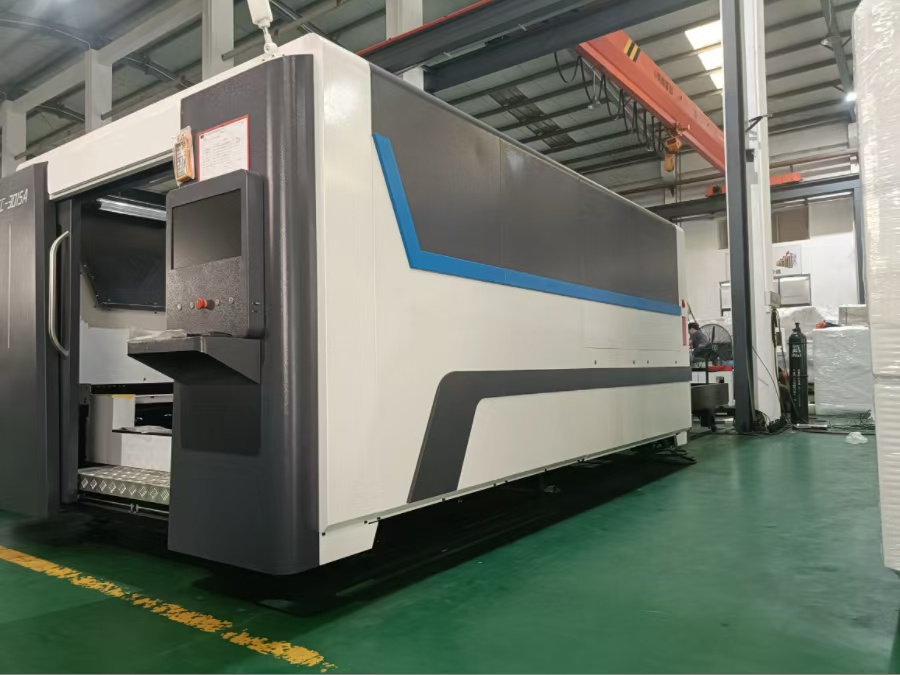

Related product links

Cutter News

Cutter News