- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

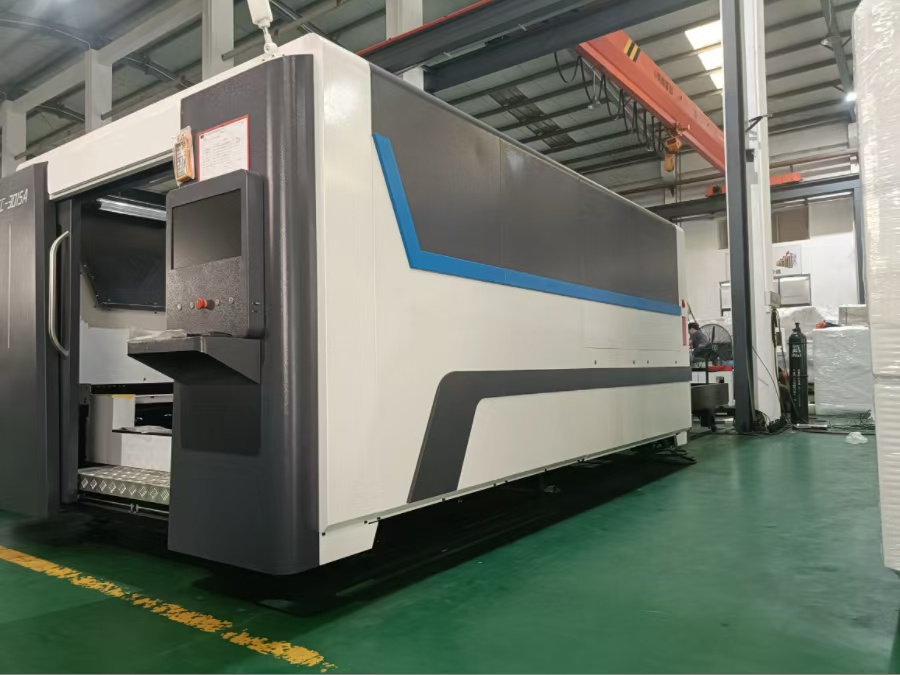

Functions of fiber laser cutting machine?

Fiber laser cutting machine is a high-precision and high-efficiency laser processing equipment, and its functions are mainly reflected in the following aspects:

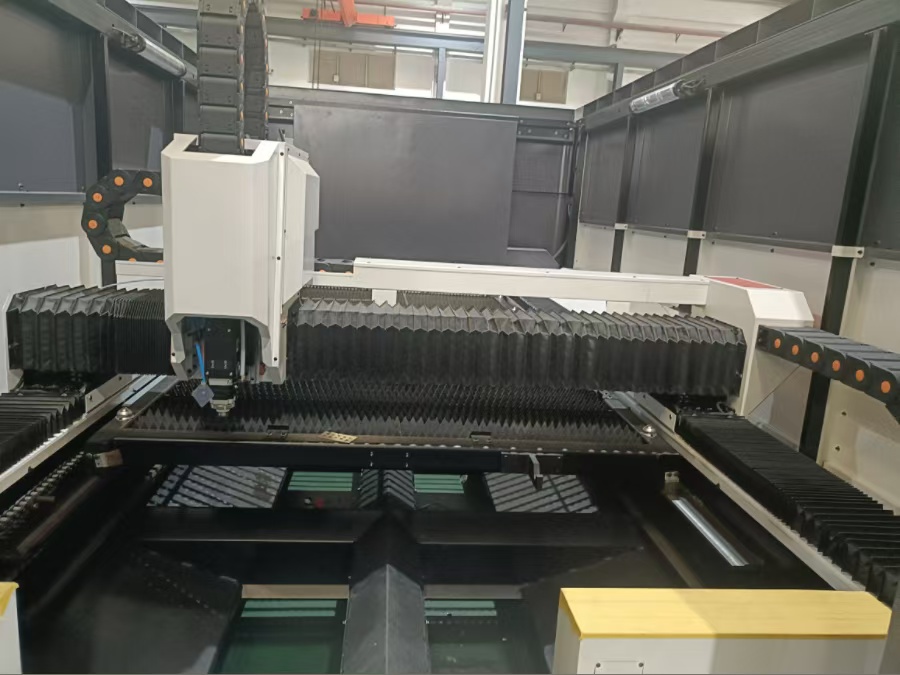

1. Cutting function

Accurate cutting:

The fiber laser cutting machine uses a high-energy laser beam to irradiate the surface of the material, so that the material quickly melts, vaporizes or reaches the ignition point, and blows away the melted or burned material through a high-speed airflow, thereby achieving accurate cutting.

Its laser beam has a small focused spot and high energy density, which can achieve accurate cutting of thin plates, narrow incision width, and high cutting accuracy.

Efficient cutting:

The fiber laser cutting machine has a fast transmission speed, which can achieve high-speed cutting and improve production efficiency.

Especially compared with the CO2 laser cutting machine of the same power, the fiber laser cutting machine has a faster cutting speed, which is about twice that of the CO2 laser cutting machine.

2. Marking function

Fiber laser cutting machines are not limited to cutting, but also have marking functions. Through accurate control of the laser beam, various patterns, texts or QR codes and other information can be engraved on the surface of the material to meet the needs of personalized customization and identification.

3. Automatic identification and intelligent typesetting

Some high-quality fiber laser cutting machines are also equipped with automatic identification systems and intelligent typesetting functions.

These systems can automatically identify various colored patterns and texts on metal sheets, and automatically find edges and cut according to actual needs.

At the same time, they can also automatically typeset graphics according to different rules and sizes, improve material utilization, save energy consumption, and improve efficiency.

4. Processing flexibility

The fiber laser cutting machine has high flexibility in processing. It can perform both plane cutting and bevel cutting with neat and smooth edges.

In addition, combined with equipment such as robotic arms, it can also perform three-dimensional cutting, replacing the originally imported five-axis laser cutting machine to meet more complex processing needs.

5. Energy saving and environmental protection

The fiber laser cutting machine also performs outstandingly in energy saving and environmental protection. Its photoelectric conversion efficiency is high, and the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machines.

At the same time, the fiber laser only requires electrical energy when running, without additional laser working gas, which reduces the operation and maintenance costs.

In addition, the mechanical structure of the fiber laser cutting machine is simple, which reduces mechanical failures and maintenance costs, and the overall maintenance cost is relatively low.

6. Wide application

The fiber laser cutting machine is widely used in sheet metal, machinery manufacturing, metal processing and other fields. It can cut a variety of metal materials such as stainless steel, carbon steel, aluminum, and is suitable for sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery and other manufacturing and processing industries.

Related product links

Cutter News

Cutter News