- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

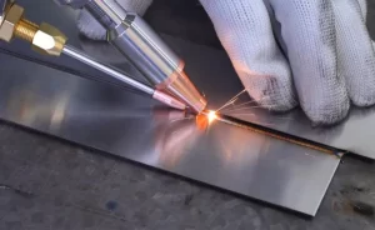

What Should I Do If Cracks Appear During Laser Welding? Troubleshooting

With the improvement of technology level, the current manufacturing processing method has changed from traditional contact processing to laser non-contact processing to improve welding efficiency and welding effect. However, various problems will still be encountered during actual use that affect the welding effect. Below, Riselaser will briefly explain what to do if cracks occur during laser welding and how to deal with some common faults.

I. Cracks appear during the welding of the laser welding machine

1. The protective gas flow rate is too large, which can be solved by reducing the protective gas flow rate.

2. The cooling speed of the workpiece is too fast. The temperature of the cooling water on the fixture should be adjusted to increase the water temperature.

3. The workpiece has not been cleaned properly. In this case, the workpiece needs to be cleaned again.

4. If the fitting gap between the workpieces is too large or there are burrs, the machining accuracy of the workpieces should be improved.

II. Insufficient welding penetration of laser welding machine

1. The laser energy is not enough, which can be solved by increasing the pulse width and current.

2. The defocus amount of the focusing mirror is wrong. The defocus amount should be adjusted to a position closer to the focus (but no splashes are allowed).

III. The laser beam of the laser welding machine is weakened

1. The cooling water is contaminated or the cooling water has not been replaced for a long time. This can be solved by replacing the cooling water and cleaning the UV filter glass tube and xenon lamp.

2. If the focusing lens or the resonant cavity diaphragm of the laser is damaged or contaminated, it should be replaced or cleaned in time.

3. The main optical path laser is shifted, adjust the main optical path full-reflective and semi-reflective diaphragms, use image paper to check and round the light spot.

4. The laser is not output from the center of the copper gas nozzle under the focusing head. Adjust the 45-degree reflective diaphragm so that the laser is output from the center of the gas nozzle.

5. If the shutters are not fully opened, check and add lubricating oil to the shutter connectors to make the connectors mechanically smooth.

I. Daily maintenance methods of laser welding machine

1. Keep the chiller clean: regularly disassemble and clean the dust filter of the chiller and clean the dust on the condenser of the chiller.

2. Ensure the purity of cooling water: replace circulating cooling water and filter elements every month.

3. Replace resin: Always pay attention to the color change of the ion exchange column in the cooling system. Once the color of the resin in the exchange column is found to be dark brown or even black, the resin should be replaced immediately

4. Ensure that the laser chiller is in a working environment below 40°C, and ensure that the air outlet and air inlet of the chiller are well-ventilated.

5. Regularly check whether there is any leakage at the water pipe joints. If there is water leakage, please tighten the screw there until there is no water leakage.

6. Winter maintenance: In addition to daily maintenance, you must also pay attention to anti-freeze. To ensure the normal use of the laser, the ambient temperature should not be lower than 5 degrees Celsius. Antifreeze can also be added according to the actual situation of the chiller.

7. When the chiller is in a shutdown state or has been shut down for a long time due to a fault, try to drain the water in the chiller water tank and pipelines.

The above are the troubleshooting methods on what to do if cracks occur during the welding of the laser welding machine and some maintenance methods of the cooling system of the laser welding machine.

Related product links

Welder News

Welder News