- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Why choose an air-cooled fiber laser welding machine?

Advantage 1: Cost-effectiveness of air-cooled fiber laser welding

1. Reduced overall operating costs: Although air-cooled laser welding machines may be more expensive initially, they can save a lot of money in the long run. By eliminating the need for a water cooling system, you can save the cost of purchasing and maintaining chillers and water circulation equipment. This means a more streamlined system and lower maintenance costs, especially in extremely cold areas, where water-cooled machines would otherwise require antifreeze and additional water heating systems.

2. Simplified installation and mobility: Air-cooled systems are compact and lightweight because they do not rely on heavy water tanks or circulation systems. This makes them easier to transport and install. This is especially useful in mobile applications, where the machine may need to be moved frequently during operation.

3. Improved performance in cold climates: In cold environments, water-cooled systems require additional settings, such as heating mechanisms or antifreeze, to prevent the water from freezing. On the other hand, air-cooled systems completely avoid this problem because they do not rely on liquid cooling. This reduces operational complexity and the additional costs associated with keeping water-based systems running smoothly in sub-zero temperatures.

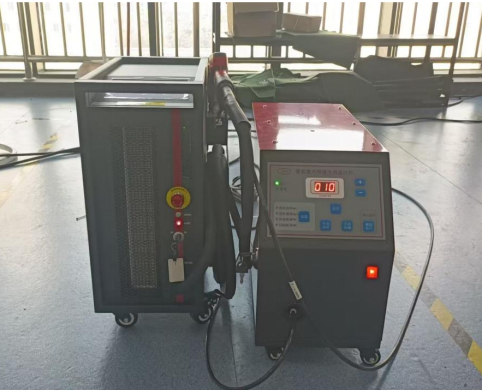

Advantage 2: Compact and portable design

Space in the shop is at a premium. I get it. It’s not easy to fit all the equipment you need in without making your shop feel like a crowded airport. The good news? Air-cooled fiber laser welders are compact and lightweight, weighing only 26 to 48 kg. They’re small enough to squeeze into the tightest spaces, and they’re easy to move around thanks to their wheels.

Advantage 3: Low maintenance and long service life

No one wants to waste time dealing with maintenance issues, and water systems are often a headache—prone to leaks, failures, and freezing in the colder months. With an air-cooled fiber laser welder, you don’t have to worry about that. No water, no problem.

Fiber lasers are known for their durability, typically lasting up to 100,000 hours, while CO2 lasers last about 30,000 hours. This extra-long service life ensures years of reliable performance with minimal maintenance interruptions.

The long service life of a fiber laser also means a better return on investment. Fewer repairs and less downtime means lower costs and greater operational efficiency. By investing in an air-cooled fiber laser welding machine, you can get a durable, cost-effective solution for your business.

Benefit 4: Improve welding precision and quality

Welding precision is critical, and fiber lasers excel in this regard. Air cooling technology ensures that the machine continues to run without overheating, providing perfect, high-quality welds every time. The system is especially useful when working with delicate materials or thin metals, as precise control is essential to avoid deformation and ensure smooth, clean welds.

One of the main advantages of fiber lasers is the ability to produce consistent, repeatable welds. Fine control over laser parameters ensures uniformity, which is critical in high-volume production environments. This reduces the need for touch-ups or rework, ultimately improving overall production efficiency and reducing operating costs. The air cooling system further enhances this by maintaining stable performance without complex maintenance.

Incorporating air-cooled fiber lasers into your operation means you will get better precision, higher efficiency, and consistent quality in every weld, making it the first choice for industries that require reliability and high performance.

Benefit 5: Environmental protection and energy saving

This is exactly where I want to be environmentally friendly - because who doesn't like to save the earth and save money at the same time? Air-cooled fiber laser welding machines consume less energy overall than traditional methods. This not only means lower operating costs, but also a lower carbon footprint.

Welder News

Welder News