-

Metal sheet processing tool: laser cutting machine!

With the rapid development of modern industrial technology, the metal sheet processing industry is facing unprecedented changes. In this field, laser cutting machines have become a powerful processing tool due to their high efficiency, accuracy, and environmental protection, brin...Oct 10,2024Learn more -

Laser cutting acrylic billboards: the perfect display of modern technology!

With the continuous development of science and technology, the production process of billboards is also constantly improving. Traditional billboard production methods, such as inkjet printing and engraving, are low-cost, but the results are often unsatisfactory. Nowadays, a new b...Oct 09,2024Learn more -

What are the advantages of laser cutting machines in food machinery applications?

The safety and sanitation of food machinery has a great impact on the health of consumers, so the requirements of high standards and high cleanliness increase the difficulty of equipment production for food machinery manufacturers. So how to solve these problems? Here is how SAN ...Oct 09,2024Learn more -

Four major factors affecting the speed of laser marking machines!

Generally speaking, the main reasons affecting the speed of laser marking machines are: one is the equipment itself, and the other is the processing workplace. The main reasons for the equipment itself are laser frequency, laser spot mode and light speed divergence angle laser po...Oct 09,2024Learn more -

How to increase the laser marking speed of the laser marking machine?

1. Sufficient powerThe power of the fiber laser marking machine is 20W, 30W, 50W, 100W, etc. The higher the power, the more expensive it is. Generally speaking, 20W is enough for ordinary metal materials, but you can't buy 20W directly because you save money. Please take samp...Oct 09,2024Learn more -

Laser marking equipment is becoming more and more diverse, and its application range is becoming wider and wider!

1. UV laser marking machineThe UV laser is developed using a 355nm UV laser. It uses the third-order intracavity frequency doubling technology and uses laser energy to break the bonds between atoms or molecules, turning them into small molecules and evaporating them. Compared wit...Oct 09,2024Learn more -

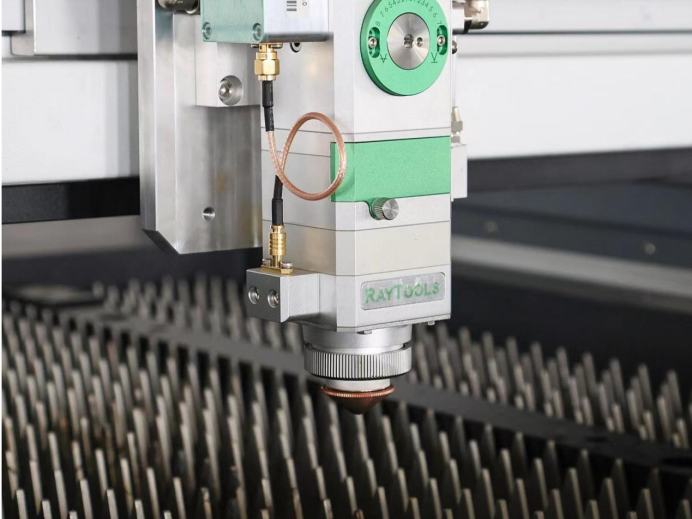

Analysis of the function of laser cutting machine!

1) Machine tool mainframe: The machine tool part of the laser cutting machine, the mechanical part that realizes the movement of the X, Y, and Z axes, including the cutting work platform. It is used to place the workplacee to be cut and can move correctly and accurately acco...Oct 09,2024Learn more -

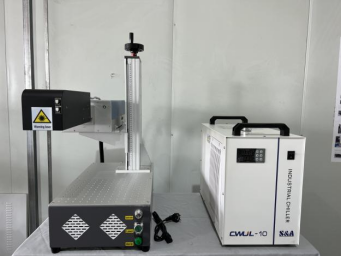

How To Choose Common Accessories For Fiber Laser Cutting Machine?

Mainly the main components of the optical fiber machine tool: Laser Source, Laser Cutting/Welding Head, Water Chiller, and the machine itself. We sells all the accessory products included in the whole machine tool. At the same time, the most commonly used consumables are the...Sep 25,2024Learn more -

Sandblasing vs Laser Cleaning!

· Small grainsSandblasting (also referred to as grit blasting) has its name from the sand that was first used to blast a work layer at high speed to remove an unwanted layer on the surface. To get to an optimal result, other grains like ceramic, glass, soda grains, etc. are used ...Sep 25,2024Learn more -

What kind of pollutions are suitable for laser cleaning?

The first thing that comes to mind about laser cleaning is the removal of rust. The possibilities are so much wider than that, though. The most important benchmark is that the contaminated layer isn’t reflective and isn’t too thick. The problem with reflection is the fact th...Sep 25,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News