-

Laser welding machine precision welding makes jewelry more durable!

Many jewelry are very delicate and short, and it is very inconvenient to process, especially when welding decorative materials on them and welding the bracelet parts. Laser welding machine is a commonly used equipment that can well ensure the quality of jewelry products without a...Nov 07,2024Learn more -

Common faults of laser welding machines and solutions!

Laser technology has developed steadily in various industries. In the process of using laser welding equipment, some faults will occur more or less. In order to reduce the number of faults of laser welding machines and increase work efficiency, we must understand the working prin...Nov 06,2024Learn more -

How to reduce the impact of metal laser welding machine failure?

Modern factories usually connect metal laser welding machines to the entire production line, which is responsible for the welding of some workplace. With the increasing degree of industrial automation, the number of products that can be produced in a production line within 1 minu...Nov 06,2024Learn more -

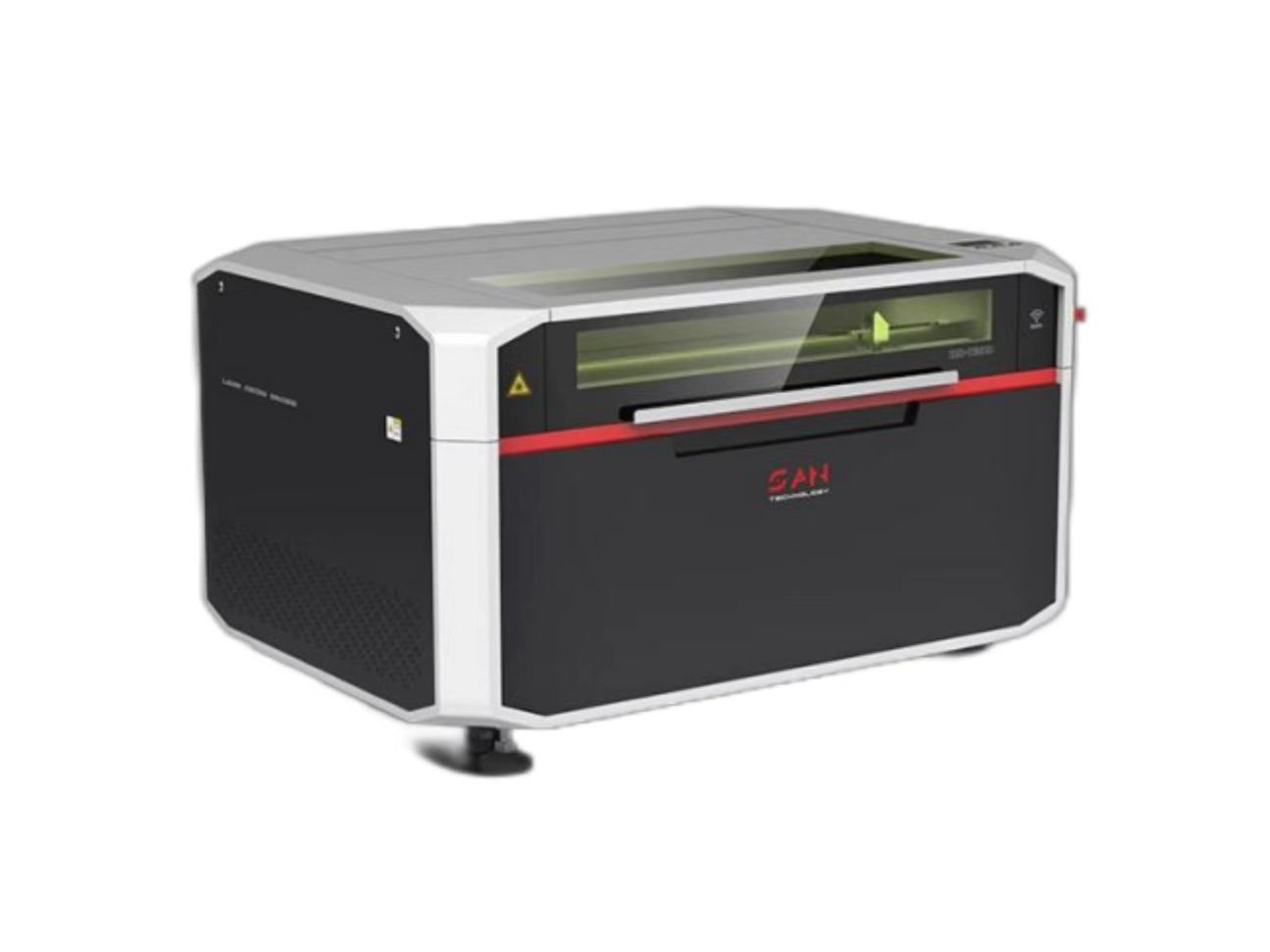

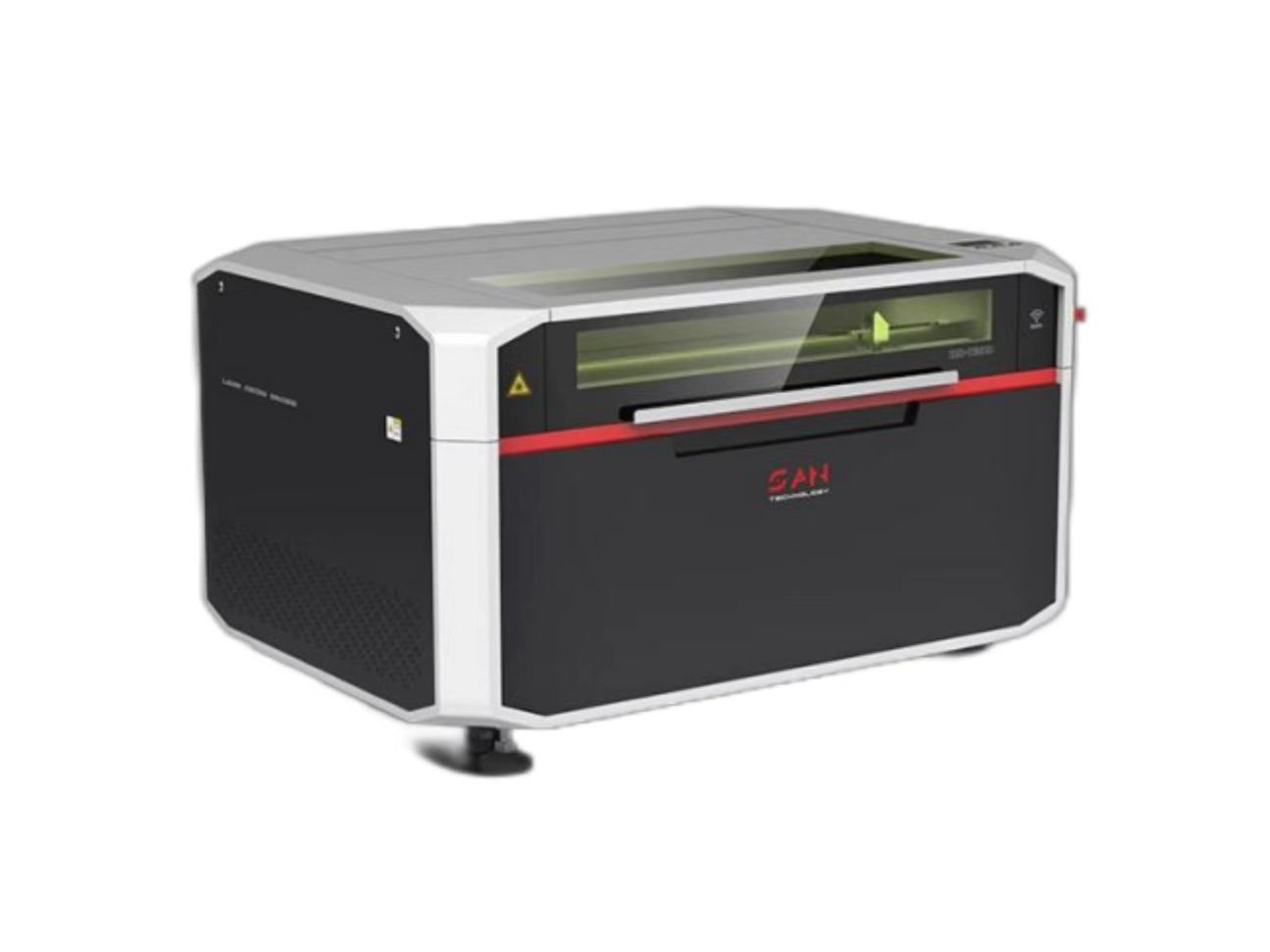

Application fields and equipment advantages of CO2 non-metal laser cutting machine!

CO2 non-metallic laser cutting machines have a wide range of applications, including but not limited to:1. Cutting of wood, acrylic, glass, ceramics, plastic, rubber, paper and other materials.2. Making signs, furniture, toys, watch lenses, etc.3. Engraving and marking, such as e...Nov 05,2024Learn more -

The Practical Application And Advantages Of Laser Cutting Machine In Sheet Metal Processing

(1) Use programming software to improve laser cutting efficiency. Laser cutting can effectively use the advantages of programming software, greatly improve the utilization rate of thin-plate materials, reduce the use and waste of materials, and reduce the labor intensity and stre...Nov 05,2024Learn more -

Is Laser Technology Also Related To The Clothing Industry?

Since the birth of laser, it has been hailed as "the fastest knife" and "the most accurate ruler". How can the clothing industry keep such good tools away?At present, laser equipment has been widely penetrated in the clothing industry, and many traditional pro...Nov 05,2024Learn more -

Three Kinds Of Laser Welding Technology Commonly Used In Automobile!

With the development of science and technology, laser welding machine is more and more used in automobile. In fact, the laser welding seam is long, deep, wide, and the weld consistency is better, which greatly improves the adhesion and welding strength between plates. Therefore, ...Nov 04,2024Learn more -

What Is YAG Laser Marking Machine?

YAG Laser Marking machine series of models with the highest cost-effective high-end products-semiconductor laser marking machine.In recent years, with the reduction of manufacturing costs has replaced the lamp pump laser marking machine has become the procurement preferred model ...Nov 04,2024Learn more -

Can laser rust removal be used in different industries?

Of course! One of the coolest things about laser rust removal machines is their versatility. They are used in industries ranging from automotive and aerospace to cultural heritage restoration. In the automotive sector, lasers help remove rust from car parts, making refurbishment ...Nov 04,2024Learn more -

Comparison of CO2, YAG and fiber laser cutting machines!

I believe that after reading this article, you will have a general understanding of the cutting materials, cutting thickness, watts, and corresponding industries of the laser cutter, and you will not make blind choices when purchasing. Let's first introduce the principle...Nov 04,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News