-

Main characteristics of stainless steel letter laser cutting!

Main characteristics of stainless steel letter laser cutting: Nowadays, people use laser cutting more. Products made by laser cutting are of good quality, high precision, and fast speed, so stainless steel letter laser cutting is often chosen for stainless steel letter or other h...Nov 20,2024Learn more -

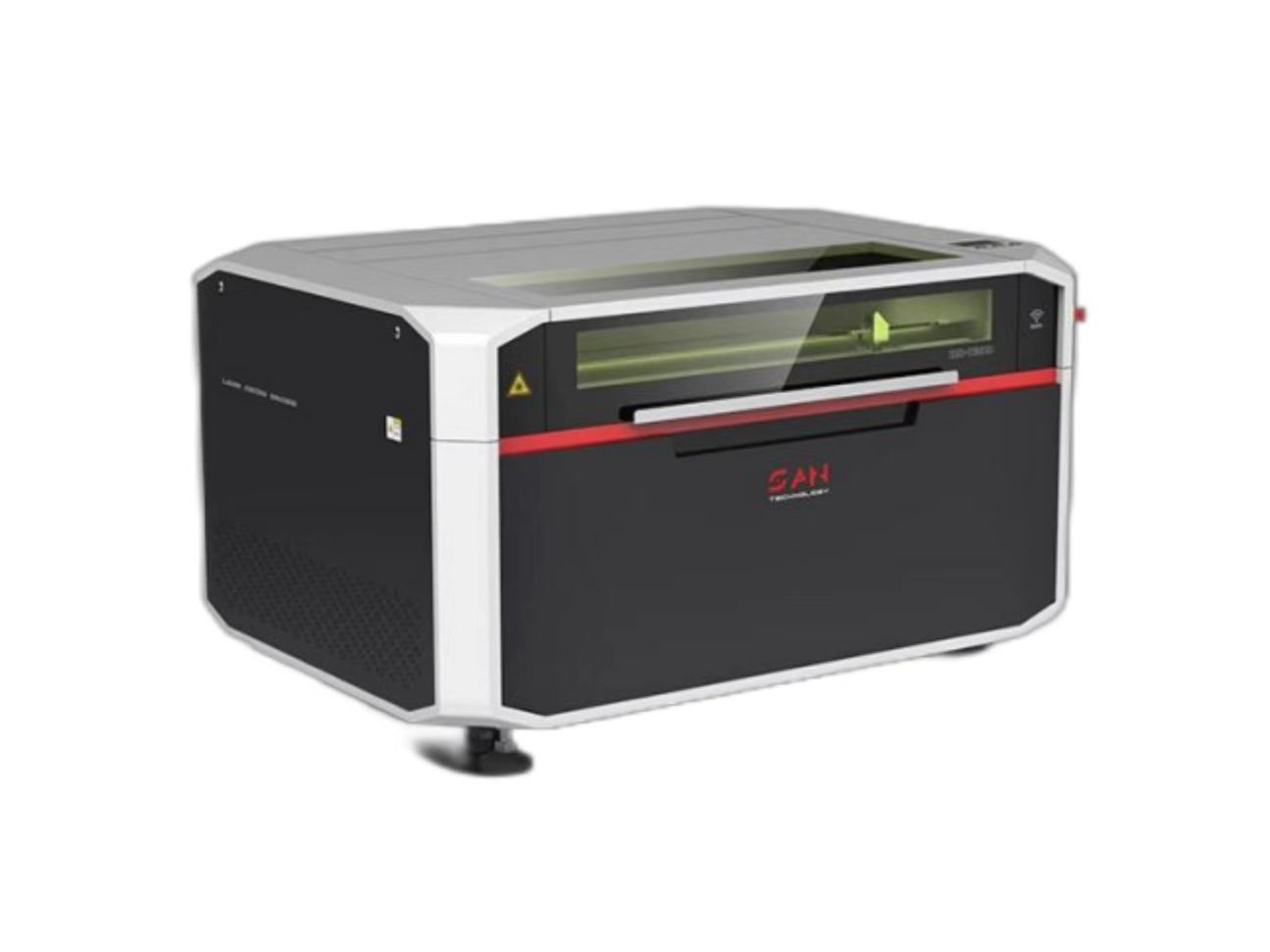

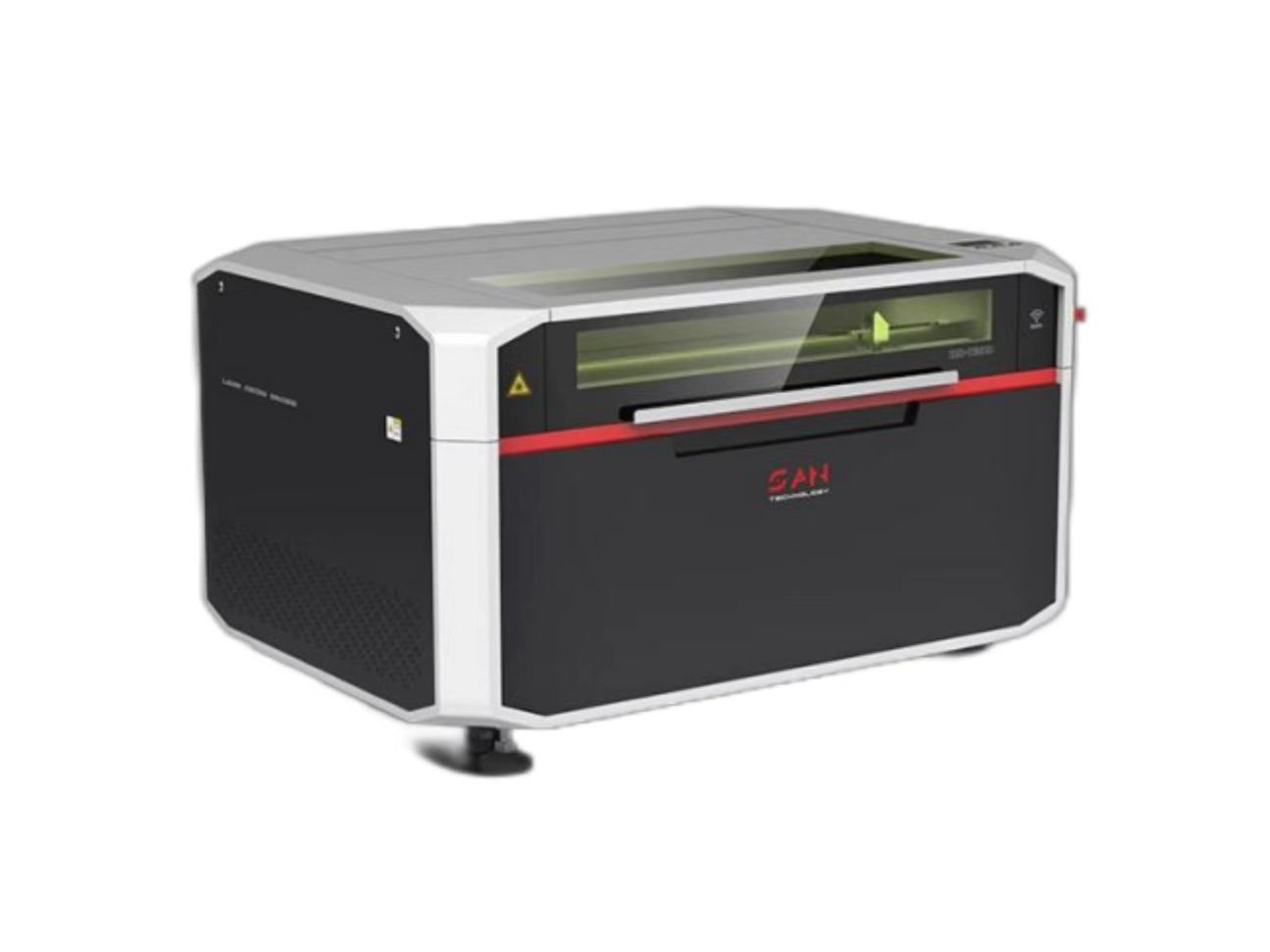

Application fields and equipment advantages of CO2 non-metal laser cutting machine!

CO2 non-metallic laser cutting machines have a wide range of applications, including but not limited to:1. Cutting of wood, acrylic, glass, ceramics, plastic, rubber, paper and other materials.2. Making signs, furniture, toys, watch lenses, etc.3. Engraving and marking, such as e...Nov 05,2024Learn more -

The Practical Application And Advantages Of Laser Cutting Machine In Sheet Metal Processing

(1) Use programming software to improve laser cutting efficiency. Laser cutting can effectively use the advantages of programming software, greatly improve the utilization rate of thin-plate materials, reduce the use and waste of materials, and reduce the labor intensity and stre...Nov 05,2024Learn more -

Is Laser Technology Also Related To The Clothing Industry?

Since the birth of laser, it has been hailed as "the fastest knife" and "the most accurate ruler". How can the clothing industry keep such good tools away?At present, laser equipment has been widely penetrated in the clothing industry, and many traditional pro...Nov 05,2024Learn more -

Comparison of CO2, YAG and fiber laser cutting machines!

I believe that after reading this article, you will have a general understanding of the cutting materials, cutting thickness, watts, and corresponding industries of the laser cutter, and you will not make blind choices when purchasing. Let's first introduce the principle...Nov 04,2024Learn more -

Comparison of common metal cutting processes!

In recent years, my country's manufacturing industry has developed rapidly. As a core process of the manufacturing industry, the efficiency and quality of metal processing will greatly affect the development of the manufacturing industry. Metal processing is to process the me...Nov 01,2024Learn more -

Laser cutting machine operation process description!

Preparation before using the laser cutting machine1. Before using, check whether the power supply voltage is consistent with the rated voltage of the machine to avoid unnecessary damage.2. Check whether there are foreign objects and residues on the machine table to avoid affectin...Oct 31,2024Learn more -

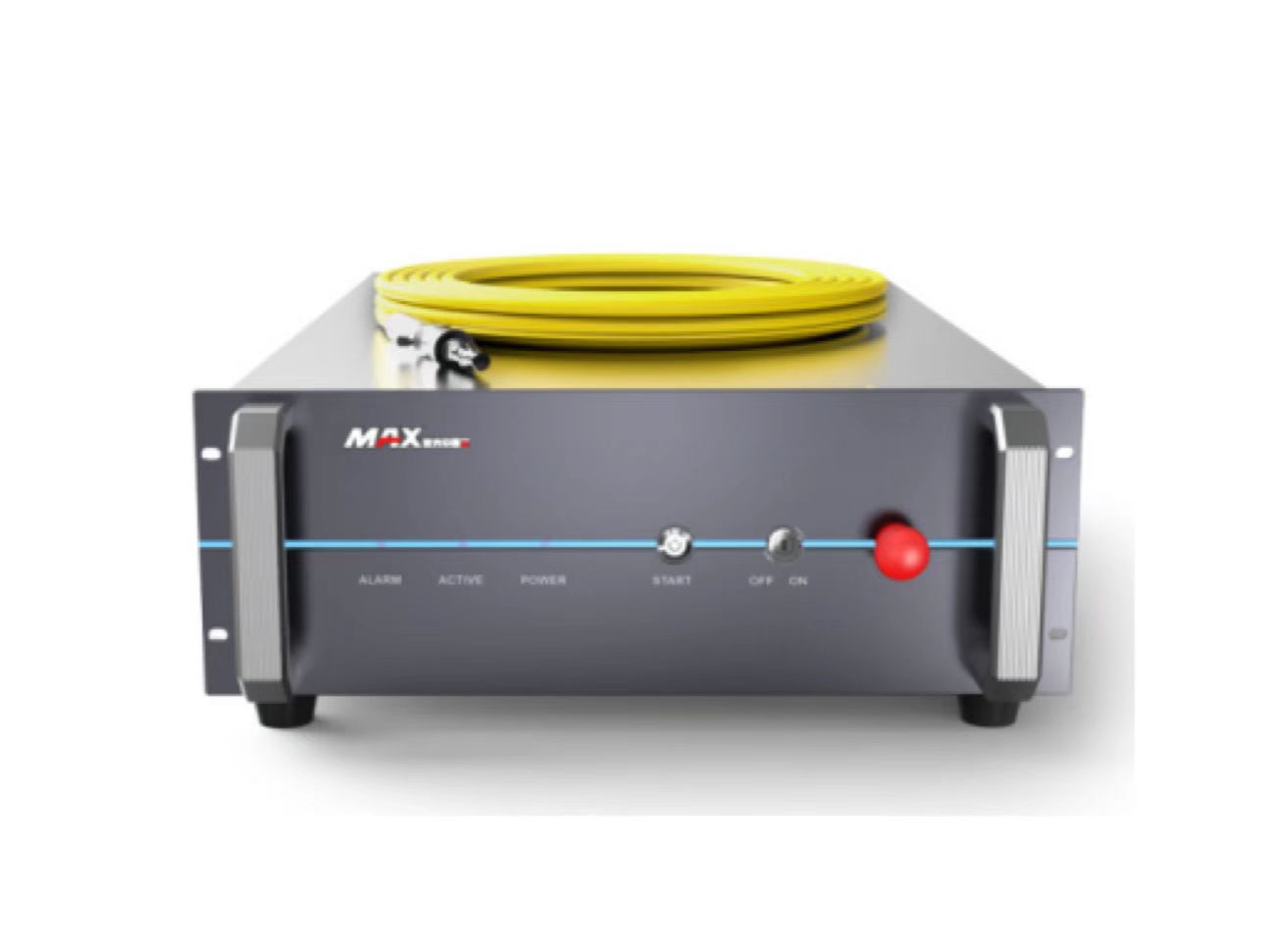

Working principle of fiber laser!

Working principle: Optical fiber is a solid glass fiber drawn with SiO2 as the matrix material. Its light guiding principle is to use the total reflection principle of light, that is, when light is incident from a light-dense medium with a large refractive index to a light-sparse...Oct 31,2024Learn more -

Breaking through the three major technical difficulties of high-power laser cutting!

With its unparalleled advantages such as large cutting format, fast cutting speed, and ability to cut thicker plates, high-power laser cutting has been widely recognized by the market. However, since high-power laser cutting technology is still in the early stages of popularizati...Oct 31,2024Learn more -

How to judge the cutting quality of precision laser cutting machine?

Precision laser cutting machine has not had a very standard cutting quality until now, most of them are. After the product is cut, it is judged by this. However, it is not known that there are many factors that affect the cutting quality. In our daily use, if we are careful, we w...Oct 28,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Cutter News

Cutter News