-

Differences Between Nanosecond, Picosecond, and Femtosecond Lasers!

Lasers are used in a wide range of industries, and their effectiveness depends on pulse duration. In this article, we will discuss three types of lasers that are primarily differentiated by pulse duration: nanosecond, picosecond, and femtosecond lasers.1.Nanosecond lasers have a ...Jul 22,2024Learn more -

9 Tips to Reduce Heat Effects of Laser Marking!

1. Optimizing the focus of the laser beamOptimizing the focus of the laser beam can make the energy more concentrated, causing the material to vaporize instead of burn. Specifically, this can be achieved by using lenses with shorter focal lengths and larger expansion mirrors...Jul 22,2024Learn more -

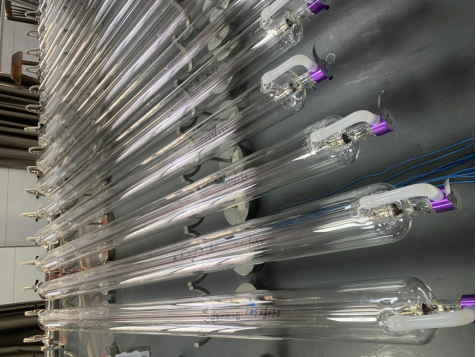

Understanding CO2 Lasers!

Have you ever wondered how lasers revolutionized everything from surgery to cutting metal? This article dives into the fascinating world of CO2 lasers, explaining their principles and structure. By reading, you’ll uncover how these powerful tools work. Get ready to explore the ma...Jul 16,2024Learn more -

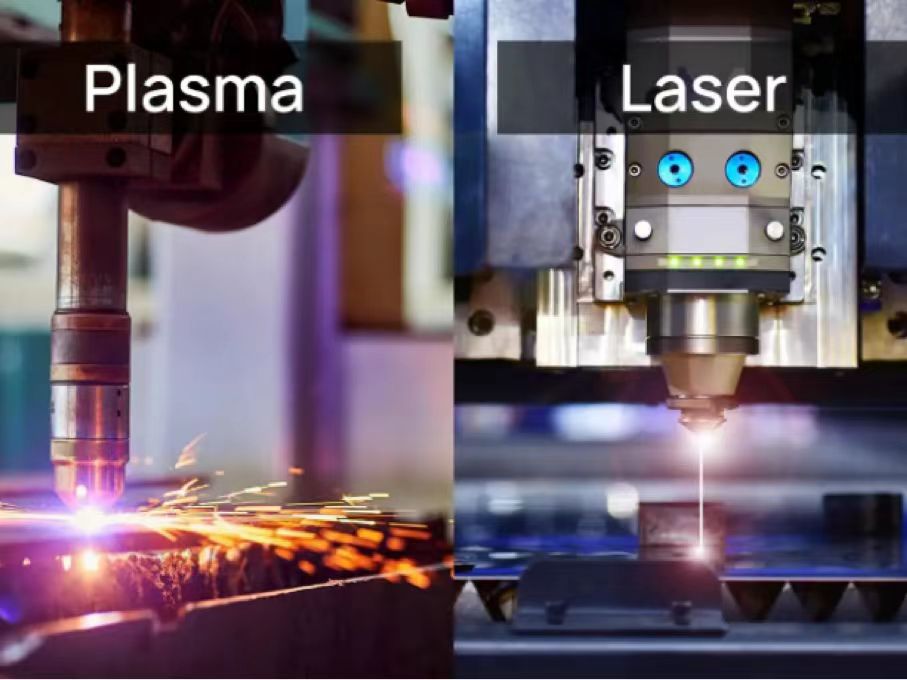

Plasma Cutting vs Laser Cutting: The Differences Explained!

In the rapidly evolving world of metal cutting, a battle rages between laser and plasma. As technology advances, the landscape shifts.With the rise of multi-kilowatt lasers, and now with the widespread adoption of 60kW lasers, laser cutting is expanding into the realm of medium a...Jul 16,2024Learn more -

How Laser Power Affects Welding: Explained!

What determines the quality and efficiency of a weld? In laser welding, the power setting is crucial. This article dives into how laser power impacts welding outcomes, from penetration depth to welding speed. Readers will learn the principles behind laser welding, the relationshi...Jul 16,2024Learn more -

Handheld Laser Welding Machine Preparation Before Use!

Handheld Laser Welding Machine Preparation Before Use1)Cooling system water temperature setting: In summer (ambient temperature higher than 30 ℃) 29 ± 0.5 ℃. In winter (ambient temperature below 30 ℃) 25 ± 0.5 ℃.2)Coolant requirements:Purified water should be used as ...Jul 16,2024Learn more -

Safety and Maintenance of Metal Laser Cutting & Engraving Machine!

Laser safety guidelines for Laser Engraving Machines:· During machine operation, operators must not leave the machine unattended to avoid unnecessary loss.· When the machine is in operation, the top cover of the machine must be covered to prevent the laser fro...Jul 16,2024Learn more -

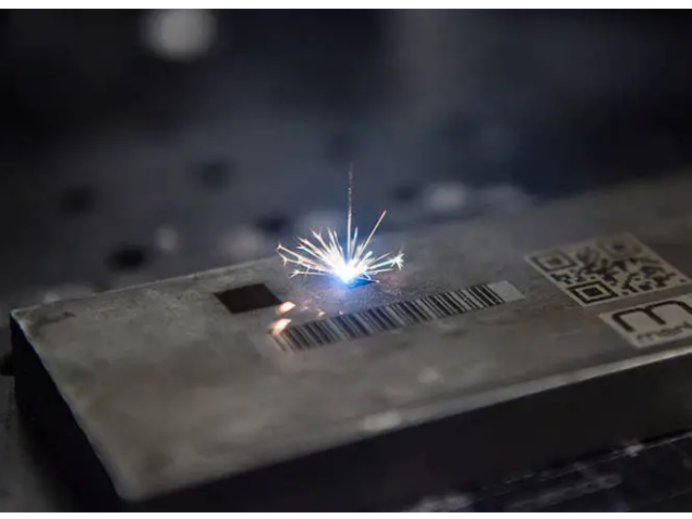

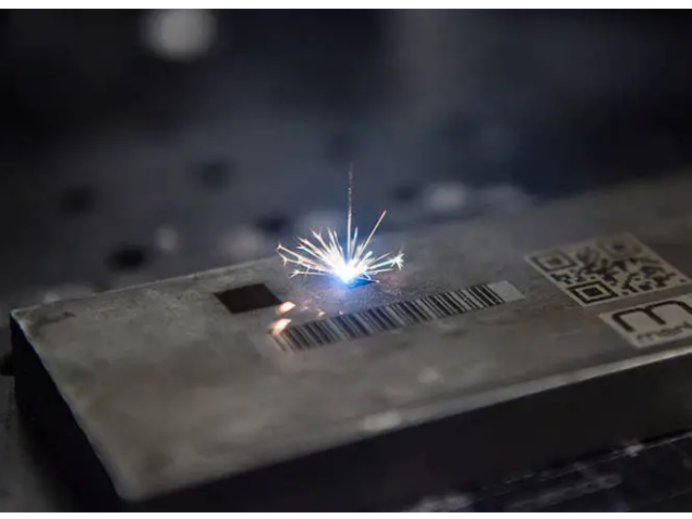

A perfect products that are very suitable for laser welding!

The advantages of laser welding machines are concentrated energy, no pollution, small welding spots, a wide range of weldable materials, strong applicability, high efficiency and high speed.The following types of products are very suitable for laser welding:1.Products with weldin...Jul 16,2024Learn more -

Precautions for laser marking machine operation!

To know the operating precautions of the marking machine, you can refer to the following matters:1. Before using the laser marking machine, first read the machine manual carefully and operate the machine according to the correct steps.2. When the laser marking machine is working,...Jul 16,2024Learn more -

Winter antifreeze measures for fiber laser cutting machines!

Since November, winter has begun in my country, the temperature is getting lower and lower, and many northern regions have experienced a heavy snow. When the temperature drops and the weather turns cold, in order to ensure the normal operation of the fiber laser cutting machine i...Jul 12,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

News

News